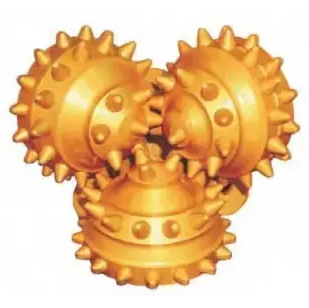

Mill tooth tricone bits also called steel cone cone bits), it are made of high-strength alloy materials from tricone cone bit manufacturers. We not only try to improve the impact resistance of teeth, but also comprehensively improves the shearing effect and sliding distance of the drill. Now, this accessory can be well used in modern drilling engineering, which can not only effectively reduce the possibility of broken teeth, but also optimize the arrangement of the number of teeth and the number of teeth, and make full use of the function of the tooth milling bit. In the manufacturing process of the bit cone, it uses an inner hole welded antifriction alloy, which can improve the bite ability of the bearing to a certain extent, and also installed to limit the pressure difference and prevent mud from entering the lubrication system Rubber sealing device. The capacity and service life of the seal lubrication system of the drill bit can be significantly improved.

Mill tooth tricone bits also called steel cone cone bits), it are made of high-strength alloy materials from tricone cone bit manufacturers. We not only try to improve the impact resistance of teeth, but also comprehensively improves the shearing effect and sliding distance of the drill. Now, this accessory can be well used in modern drilling engineering, which can not only effectively reduce the possibility of broken teeth, but also optimize the arrangement of the number of teeth and the number of teeth, and make full use of the function of the tooth milling bit. In the manufacturing process of the bit cone, it uses an inner hole welded antifriction alloy, which can improve the bite ability of the bearing to a certain extent, and also installed to limit the pressure difference and prevent mud from entering the lubrication system Rubber sealing device. The capacity and service life of the seal lubrication system of the drill bit can be significantly improved.

| Basical Specification | |

| Size of Rock Bit | 17 1/2" |

| 444.5 mm | |

| Bit Type | Steel Tooth Tricone Bit/ Milled tooth Tricone Bit |

| Thread Connection | 7 5/8 API REG PIN |

| IADC Code | IADC 126 |

| Bearing Type | Journal Sealed Roller Bearing |

| Bearing Seal | Rubber Seal |

| Heel Protection | Unvailable |

| Shirttail Protection | Available |

| Circulation Type | Mud Circulation |

| Drilling Condition | Rotary drilling,high temp drilling,deep drilling,motor drilling |

| Nozzles | 3 |

| Operating Parameters | |

| WOB (Weight On Bit) | 299,64-84,897 lbs |

| 133-378KN | |

| RPM(r/min) | 60~180 |

| Formation | Soft formations with low compressive strength and high drillability,such as mudstone,gypsum,salt,soft limestone ,etc. |

Steel tooth tricone bits are also named milled tooth tricone bit, "steel" means the teeth material is steel, actually it is a type of special steels 15MnNi4Mo and the surface of steel material is hard faced by Tungsten Carbide to increase wear resistance Milled means the teeth is machined by milling machine, so steel tooth tricone bits have another names "mill tooth tricone bits" or "milled tooth tricone bits". 26 inches is always diameter of the first hole in deep well drilling, the formations are always soft in shallow section, so 26" is widely used in worldwide

Steel tooth tricone bits are also named milled tooth tricone bit, "steel" means the teeth material is steel, actually it is a type of special steels 15MnNi4Mo and the surface of steel material is hard faced by Tungsten Carbide to increase wear resistance Milled means the teeth is machined by milling machine, so steel tooth tricone bits have another names "mill tooth tricone bits" or "milled tooth tricone bits". 26 inches is always diameter of the first hole in deep well drilling, the formations are always soft in shallow section, so 26" is widely used in worldwide