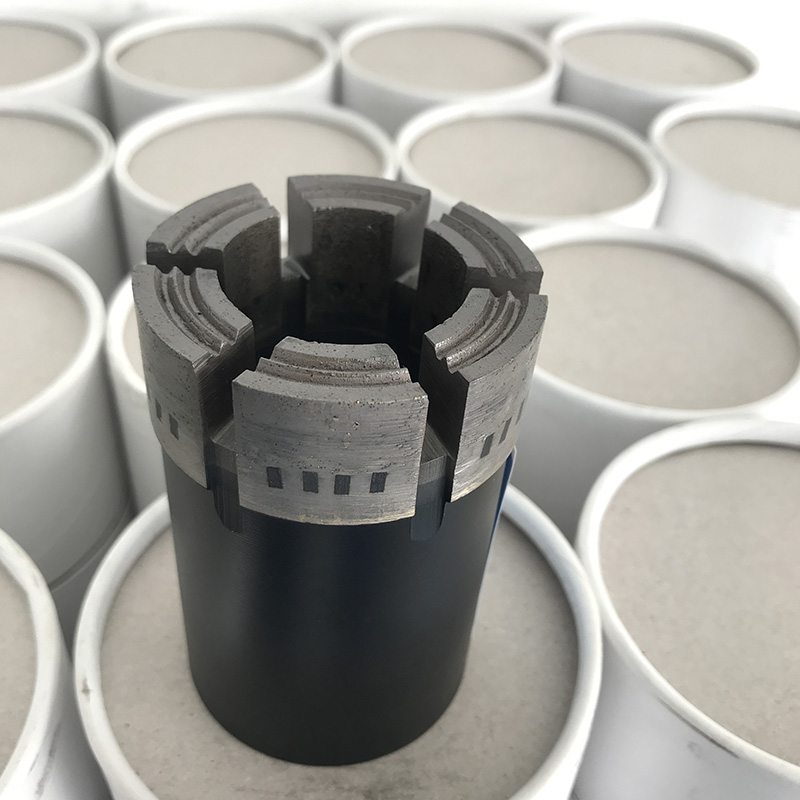

The surface set diamond bit is produced from a single layer of natural diamond setting on the surface of bit crown with hard matrix. Surface set diamond bit is mainly recommended for drilling soft to hard formations. Generally speaking, surface set diamond bit can provide satisfying penetration rate. To choose a right surface set for the formations drilled, we need at least consider the following aspects: diamond size, diamond grade, profile design. Principle of choosing diamond size--the harder the rocks, the smaller the diamond size should be. Profiles of surface set core bit: Semi-round: it is mostly used in the core bit with bit kerf thickness less than 11mm. It can drill various formations. The core bit with semi-round profile has long bit life, and can avoid damage; while the bit kerf thickness is over 11mm with semi-round profile can be applied in drilling abrasive formations. Stepped profile: core bit kerf thickness over 11mm usually has this kind of profile. Bit with Stepped profile can obtain high penetration rate with good stability in drilling. However, it is not recommended in fractured very abrasive formations. When the core bit of bit kerf less than 11mm has stepped profile can facilitate drilling speed and have better drilling stability.

The surface set diamond bit is produced from a single layer of natural diamond setting on the surface of bit crown with hard matrix. Surface set diamond bit is mainly recommended for drilling soft to hard formations. Generally speaking, surface set diamond bit can provide satisfying penetration rate. To choose a right surface set for the formations drilled, we need at least consider the following aspects: diamond size, diamond grade, profile design. Principle of choosing diamond size--the harder the rocks, the smaller the diamond size should be. Profiles of surface set core bit: Semi-round: it is mostly used in the core bit with bit kerf thickness less than 11mm. It can drill various formations. The core bit with semi-round profile has long bit life, and can avoid damage; while the bit kerf thickness is over 11mm with semi-round profile can be applied in drilling abrasive formations. Stepped profile: core bit kerf thickness over 11mm usually has this kind of profile. Bit with Stepped profile can obtain high penetration rate with good stability in drilling. However, it is not recommended in fractured very abrasive formations. When the core bit of bit kerf less than 11mm has stepped profile can facilitate drilling speed and have better drilling stability.

| Diamond Size | Formation Drilled |

| 10/20 SPC* | Soft formation |

| 20/30 SPC | soft to medium formation |

| 30/40 SPC | medium formation |

| 40/60 SPC | Medium to hard formation |

| < 60/80 SPC | Very hard formation |

| * SPC is short for Stone per Carat** 40/60 is Forsun standard diamond size for natural diamond core bit*** Other sizes are available as per request | |

| Diamond Grade | Formation Drilled |

| A Grade | Soft formation |

| AA grade | Soft to medium formation |

| AAA grade | Hard to very hard formation |

| * AA grade is Forsun standar diamond grade used in natural diamond core bit | |