High-Quality PDC Drill Drag Bit at Competitive Prices

By:Admin

The oil and gas industry is a highly competitive market where companies are constantly striving to improve their drilling efficiency and reduce operating costs. One of the key factors in achieving these goals is the use of high-quality drill bits, such as PDC (Polycrystalline Diamond Compact) drill drag bits. These bits are designed to provide superior performance and longevity in drilling operations, making them an essential tool for companies in the oil and gas sector.

In recent years, the market for PDC drill drag bits has become increasingly competitive, with several companies vying for a larger share of the market. The competition has led to a significant decrease in the price of these bits, making them more affordable for companies of all sizes. This has been a game-changer for many companies, as it has allowed them to invest in high-quality drill bits without breaking the bank.

One company that has been at the forefront of this price competition is {}. With a proven track record of producing high-quality PDC drill drag bits, the company has been able to offer competitive prices to its customers, making it a top choice for many drilling operations. The company's commitment to innovation and continuous improvement has allowed it to stay ahead of the competition, providing its customers with cutting-edge drill bits that offer superior performance and reliability.

The decrease in the price of PDC drill drag bits has been a welcome development for many companies in the oil and gas industry. As drilling operations continue to become more complex and demanding, the need for high-quality drill bits has never been greater. With the price of PDC drill drag bits becoming more affordable, companies can now invest in these essential tools without compromising on quality or performance.

In addition to the price competition, companies like {} have also been focusing on developing new and improved drill bit designs to meet the evolving needs of the industry. These innovations have allowed companies to achieve greater efficiency and productivity in their drilling operations, ultimately leading to cost savings and improved profitability.

As the competition in the PDC drill drag bit market continues to intensify, companies are likely to see even further decreases in prices, making these essential tools more accessible than ever before. This is great news for companies in the oil and gas industry, as it allows them to invest in high-quality drill bits without exceeding their budget.

With companies like {} leading the way in price competition and innovation, the future looks bright for the PDC drill drag bit market. As drilling operations continue to evolve, companies can expect to see even more advanced and efficient drill bit designs that will further enhance their performance and productivity.

In conclusion, the decrease in the price of PDC drill drag bits has been a game-changer for companies in the oil and gas industry. With companies like {} leading the way in price competition and innovation, companies can now invest in high-quality drill bits without breaking the bank. As the competition in the market continues to intensify, companies can expect to see even more affordable and advanced drill bit designs in the future, further enhancing their drilling efficiency and reducing operating costs.

Company News & Blog

Discover the Latest Innovations in Oil Drilling Bit Manufacturing

Oil Drilling Bit Factory Expands Operations to Meet Growing DemandWith the global demand for oil on the rise, the oil drilling bit factory is expanding its operations to meet the increasing needs of the industry. The factory, which is known for its high-quality drilling bits, has seen a surge in demand for its products and has decided to ramp up production to keep up with the growing needs of its customers.The factory, which is located in [], has been in operation for over [] years and has built a reputation for producing top-of-the-line drilling bits for oil exploration and production. The company prides itself on its state-of-the-art manufacturing facility, highly skilled workforce, and dedication to innovation and quality.In recent years, the oil and gas industry has seen a resurgence, driven by increasing global energy demands and advancements in drilling technologies. As a result, oil companies have been expanding their exploration and production activities, leading to a greater need for high-performance drilling equipment.In response to this growing demand, the oil drilling bit factory has announced plans to expand its production capacity and streamline its operations. The company has invested in new machinery and equipment to increase its manufacturing capabilities, as well as hired additional staff to support the expansion."We are excited to announce the expansion of our operations to meet the growing demand for our products," said [Company Spokesperson]. "We are committed to providing our customers with the highest quality drilling bits, and this expansion will allow us to serve them better and faster."The factory's expansion comes at a time when the oil and gas industry is facing increasing pressure to improve efficiency and reduce costs. By investing in new technology and processes, the factory aims to optimize its operations and deliver cost-effective solutions to its customers."We are constantly looking for ways to enhance our manufacturing processes and improve the performance of our products," [Company Spokesperson] added. "Our expansion efforts are focused on increasing our production capacity, while also improving our efficiency and product quality."The expansion of the oil drilling bit factory is expected to have a positive impact on the local economy, creating job opportunities and stimulating economic growth in the region. The factory's investment in new equipment and technology is also expected to benefit local suppliers and service providers, further boosting the area's economy.In addition to expanding its manufacturing capabilities, the factory is also investing in research and development to develop new and advanced drilling technologies. The company recognizes the importance of innovation in the oil and gas industry and is committed to staying at the forefront of technological advancements."We believe that innovation is key to our success in the industry," said [Company Spokesperson]. "By investing in research and development, we aim to create cutting-edge drilling solutions that will help our customers overcome challenges and achieve their production targets."The oil drilling bit factory's expansion is a testament to its commitment to meeting the evolving needs of the oil and gas industry. By increasing its production capacity, investing in technology and innovation, and supporting the local economy, the factory is poised to play a pivotal role in the industry's growth and development.

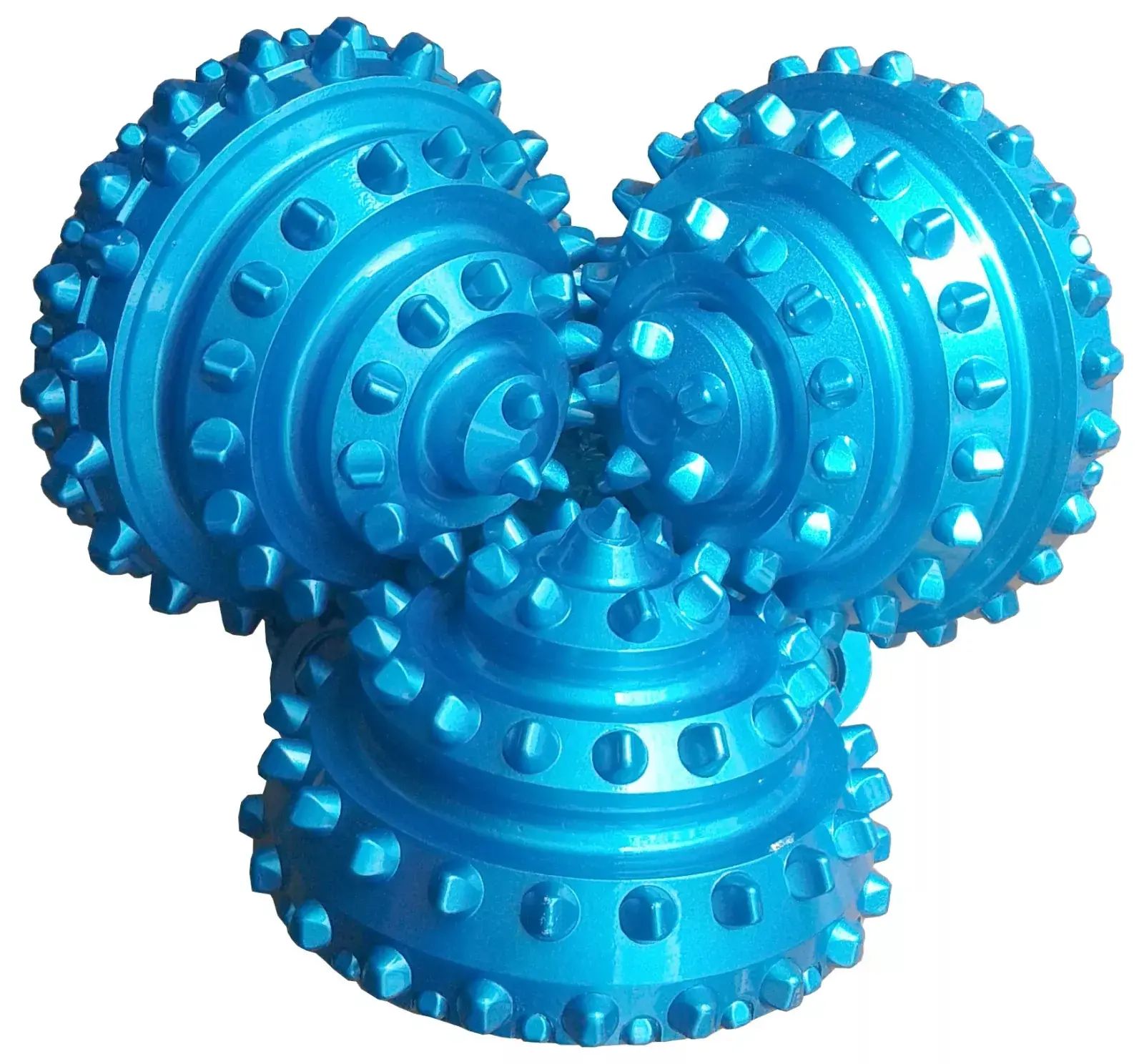

Discover the Efficient 216mm Tricone Bit (IADC117) as Reported in Recent News Articles

Tricone Bit with IADC117 216mm: Revolutionizing Drilling EfficiencyIn an era where technological advancements are rapidly transforming various industries, the energy sector stands at the forefront of innovation. The oil and gas industry, in particular, requires cutting-edge equipment to extract resources efficiently and sustainably. One vital component in this process is the tricone bit—a drilling tool renowned for its versatility and effectiveness.The tricone bit IADC117 216mm (remove brand name) has emerged as a game-changer in the drilling industry. With its unique design and advanced features, it has revolutionized the way drilling operations are carried out, enhancing productivity, and reducing costs. This versatile tool is capable of operating in various geological formations, such as soft, medium, and hard rock, making it a preferred choice for many drilling projects worldwide.The IADC117 216mm tricone bit boasts remarkable adaptability, ensuring superior performance in even the most challenging drilling conditions. Its innovative cutting structure facilitates aggressive drilling, allowing operators to achieve remarkable penetration rates. This translates into significant time and cost savings, as projects can be completed within shorter timeframes. Moreover, this tricone bit's superior durability ensures extended service life, reducing the frequency of replacements and further reducing expenses.One of the key features of the IADC117 216mm tricone bit is its advanced bearing system. Designed to withstand heavy loads and high rotational speeds, this bit can handle the demanding requirements of drilling operations with ease. Its enhanced bearing system minimizes downtime and improves overall drilling efficiency, making it an indispensable tool for drilling contractors.The IADC117 216mm tricone bit is also equipped with state-of-the-art sealing mechanisms, ensuring excellent lubrication and preventing the ingress of contaminants. This not only enhances the bit's longevity but also contributes to maintaining a clean working environment, complying with stringent environmental regulations.Furthermore, this tricone bit's unique design includes strategically placed jets that allow for efficient cleaning of the drilling face. This feature prevents build-up of cuttings and ensures smooth drilling operations, thereby increasing overall productivity. By incorporating such innovative elements, the IADC117 216mm tricone bit has set itself apart from its competitors.In addition to its exceptional technical capabilities, the IADC117 216mm tricone bit is manufactured by a leading company that is renowned for its prowess in producing high-quality drilling equipment. With a rich history of industry experience, this company has demonstrated a commitment to innovation and reliability, earning the trust of drilling contractors around the world.The company's dedication to research and development is apparent in the meticulous design and engineering of the IADC117 216mm tricone bit. Their team of experts possesses an in-depth understanding of drilling challenges, enabling them to create products that address these concerns effectively.Moreover, the company prides itself on its commitment to customer satisfaction. They not only provide top-of-the-line equipment but also offer exceptional after-sales support, including technical assistance, spare parts availability, and regular maintenance services. Consequently, drilling contractors using the IADC117 216mm tricone bit can rely on professional assistance whenever required, ensuring uninterrupted operations.The IADC117 216mm tricone bit represents a disruptive step forward in the drilling industry. Its advanced features, cutting-edge design, and exceptional performance have earned it a rightful place as a leading tool in drilling operations worldwide. As the energy sector continues to evolve, this tricone bit will undoubtedly play a crucial role in achieving more efficient and sustainable drilling practices.

New Developments in the Valve Manufacturing Industry

VALVE FACTORY (need remove brand name) is a leading manufacturer of high-quality valves for various industrial applications. With a strong focus on innovation and customer satisfaction, the company has established itself as a reliable partner for businesses across the globe. The company's commitment to excellence and continuous improvement has made it a preferred choice for customers in the Oil & Gas, Petrochemical, Power Generation, and other industries.The company offers a comprehensive range of valves, including gate valves, globe valves, check valves, and ball valves, among others. Each valve is designed and manufactured to meet the highest standards of quality and performance, ensuring reliable and efficient operation in even the most demanding environments. In addition to standard products, the company also provides custom-engineered solutions to meet specific customer requirements.The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery to ensure the highest level of precision and efficiency in the production process. The facility is staffed by a team of skilled and experienced professionals who are dedicated to delivering superior products and service to customers. From design and engineering to testing and quality control, every aspect of the manufacturing process is carefully managed to meet the company's strict standards for excellence.In addition to its manufacturing capabilities, VALVE FACTORY (need remove brand name) also has a strong commitment to research and development. The company invests heavily in innovation and technology to continuously improve its products and develop new solutions to meet the evolving needs of its customers. By staying at the forefront of industry trends and advancements, the company is able to offer cutting-edge products that deliver exceptional performance and reliability.Customer satisfaction is at the core of VALVE FACTORY's (need remove brand name) business philosophy. The company strives to build strong and long-lasting relationships with its customers by providing superior products, responsive service, and technical expertise. With a global network of sales and service partners, the company is able to provide support to customers wherever they are located, ensuring that their needs are met quickly and efficiently.As part of its commitment to quality and reliability, VALVE FACTORY (need remove brand name) maintains rigorous quality control processes throughout its operations. Every valve undergoes thorough testing and inspection to ensure that it meets the company's strict standards for performance and durability. Whether it's for a standard product or a custom-engineered solution, customers can trust that they are receiving a valve of the highest quality when they choose VALVE FACTORY (need remove brand name).In addition to its focus on quality and innovation, VALVE FACTORY (need remove brand name) is also dedicated to sustainability and environmental responsibility. The company embraces eco-friendly practices in its operations and seeks to minimize its impact on the environment. By adhering to strict environmental standards and continuously seeking ways to reduce its carbon footprint, the company is able to contribute to a more sustainable future for the planet.As a leading manufacturer of industrial valves, VALVE FACTORY (need remove brand name) is poised to continue its success and growth in the global market. With a steadfast commitment to excellence, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and the industries it serves. Whether it's for applications in the Oil & Gas, Petrochemical, Power Generation, or other sectors, customers can rely on VALVE FACTORY's (need remove brand name) expertise and products to deliver superior performance and value.

Durable Metal Mine Tricone Bit for Efficient Drilling

Metal Mine Tricone Bit Revolutionizes Rock Drilling IndustryWith the increasing demand for minerals and metals in the global market, the mining industry is constantly seeking new and innovative technologies to improve efficiency and productivity. In response to this demand, [Company Name] has introduced a groundbreaking Metal Mine Tricone Bit that is set to revolutionize the rock drilling industry.[Company Name] is a leading manufacturer of drilling equipment and has been at the forefront of technological advancements in the industry for over two decades. The Metal Mine Tricone Bit is the latest addition to their extensive range of drilling tools and is designed to provide superior performance and durability in the most challenging mining environments.The Metal Mine Tricone Bit is engineered using advanced materials and cutting-edge manufacturing processes to deliver exceptional performance in hard rock formations. Its innovative design features three interlocking cone-shaped roller cutters that rotate independently, providing a more efficient and effective drilling process. This unique design also ensures a smooth and consistent penetration rate, reducing wear and tear on the equipment and prolonging the lifespan of the bit.The superior performance of the Metal Mine Tricone Bit is further enhanced by its enhanced durability and resistance to wear and abrasion. The cutting structure is constructed from high-grade tungsten carbide and reinforced with premium alloy steel, making it capable of withstanding the extreme conditions encountered in metal mine drilling applications. This robust construction ensures minimal downtime and maintenance, resulting in increased productivity and cost savings for mining operations.The Metal Mine Tricone Bit is available in a range of sizes and configurations to cater to the specific drilling requirements of different metal mines. Whether it is for exploratory drilling, production drilling, or reaming operations, [Company Name] offers a comprehensive selection of Metal Mine Tricone Bits that are tailored to meet the unique needs of each mining project.In addition to its exceptional performance and durability, the Metal Mine Tricone Bit also prioritizes environmental sustainability. [Company Name] is committed to developing eco-friendly drilling solutions, and the Metal Mine Tricone Bit is designed to minimize environmental impact by reducing energy consumption, emissions, and waste generation during the drilling process.The introduction of the Metal Mine Tricone Bit marks a significant milestone in the evolution of rock drilling technology. Its advanced design and superior performance capabilities make it a game-changer in the metal mining industry, setting a new standard for efficiency and productivity in drilling operations.Mining companies worldwide are recognizing the benefits of the Metal Mine Tricone Bit and are increasingly adopting it for their drilling operations. With its proven track record of delivering exceptional results in the field, the Metal Mine Tricone Bit has quickly earned a reputation as the go-to solution for high-performance rock drilling in metal mines.As the mining industry continues to evolve, [Company Name] remains committed to pushing the boundaries of technological innovation and setting new benchmarks for excellence in drilling equipment. The Metal Mine Tricone Bit is a testament to their relentless pursuit of excellence and their unwavering dedication to meeting the ever-changing needs of the mining industry.In conclusion, the introduction of the Metal Mine Tricone Bit by [Company Name] represents a significant advancement in rock drilling technology, offering unparalleled performance, durability, and environmental sustainability. As metal mining operations continue to expand and evolve, the Metal Mine Tricone Bit is poised to play a pivotal role in driving efficiency and productivity, shaping the future of rock drilling in the metal mining industry.

98mm Tricone Bit Available for Purchase

We are pleased to announce that our company is now offering the 98mm tri-cone bit, ready and available in stock for our customers. These tri-cone bits are a vital tool for the oil and gas industry, and we are proud to provide top-quality products to meet our customers' drilling needs.Our company has been a leading supplier of drilling equipment for many years, and we have built a strong reputation for delivering reliable and durable products to our customers. We understand the demands of the industry, and we are committed to providing the best tools and equipment to support our customers' operations.The 98mm tri-cone bit is one of our latest offerings, and it is designed to deliver exceptional performance in a variety of drilling applications. It features a unique tri-cone design that allows for smooth and efficient drilling, even in the toughest rock formations. The bit is engineered to withstand high temperatures and pressure, making it suitable for demanding drilling operations.In addition to its durability, the 98mm tri-cone bit also offers excellent cutting performance, ensuring that our customers can achieve efficient and productive drilling operations. Whether they are drilling for oil, gas, or water, this bit is capable of delivering consistent and reliable results.At our company, we prioritize quality and customer satisfaction above all else. That's why we have subjected the 98mm tri-cone bit to rigorous testing and quality checks to ensure that it meets our high standards. Our customers can have full confidence in the performance and reliability of this product.Furthermore, our team of experts is always on hand to provide technical support and assistance to our customers. We understand that each drilling operation is unique, and we are dedicated to helping our customers find the right tools and equipment for their specific needs. Whether they require guidance on the best drilling techniques or recommendations for the most suitable equipment, our team is ready to offer valuable insights and assistance.As part of our commitment to providing a comprehensive service, we also offer customization options for the 98mm tri-cone bit. We understand that some drilling operations may require specialized tools, and we are ready to work with our customers to tailor the bit to their exact specifications. Our goal is to ensure that our customers have access to the best possible equipment to achieve their drilling objectives.In addition to the 98mm tri-cone bit, our company offers a wide range of drilling tools and equipment to meet the diverse needs of our customers. From drill bits and reamers to drilling pipes and accessories, we have everything that our customers need to support their operations.We are proud to be a trusted partner to the oil and gas industry, and we are dedicated to supporting our customers with top-quality products, technical expertise, and exceptional customer service. With the 98mm tri-cone bit now in stock, we look forward to continuing to serve our customers with the best tools and equipment for their drilling operations.

How to Drill Holes in Rocks for Beautiful Jewelry: Step-by-Step Guide

Rock jewelry has always been a favorite for people who want to add an element of natural beauty to their attire. From necklaces to earrings, rock jewelry can help you create a dynamic look that stands out from the crowd. But how do you drill holes in these rocks to create exquisite pieces of jewelry? In this tutorial, we will show you how to drill holes in rocks for jewelry using step rock drilling bits. This simple process will enable you to create your very own rock jewelry pieces that are not only beautiful but also unique. So, let's get started! Step 1: Collect Your Materials To create your own rock jewelry, you will need the following materials: 1. Rock: Choose a rock that speaks to you and has a size and shape suitable for the piece of jewelry you are planning to make. 2. Dremel with a Flex Shaft: This too is an essential tool for drilling holes in rocks. It enables you to make smooth, precise cuts in the rock. 3. Step Rock Drilling Bits: These are essential drill bits for drilling holes in rocks. They come in different sizes, so make sure to choose the right size for your rock. 4. Water: You will need water to keep the drill bits cool while drilling the rock. Step 2: Prepare the Rock Before you start drilling, you need to prepare the rock. You can do this by cleaning it thoroughly and drying it. It is essential to remove any dirt or debris from the rock surface; otherwise, it may cause your drill bit to slip while you are drilling. Step 3: Choose the Right Drill Bit Now it's time to choose the right drill bit. As mentioned earlier, you will need a step rock drilling bit. These bits come in different sizes and shapes, so make sure to select the right one for your rock. Step 4: Mark the Spot Use a marker to mark the spot where you want to drill the hole. This will help you to drill the hole precisely where you want it. Step 5: Start Drilling Now it's time to start drilling. Begin by adding water to the rock surface where you want to drill the hole. This will help cool down the drill bit and prevent it from overheating. Hold the Dremel firmly with both hands and start drilling. Make sure to apply an even pressure while drilling, and do not force the drill bit if it seems to be struggling. Once the drill bit has penetrated the rock, you can gradually increase the pressure and drill until the hole is complete. Final Thoughts Drilling holes in rocks for jewelry is a fun and creative activity. With step rock drilling bits, you can take the necessary steps to create your very own rock jewelry pieces. So, the next time you're out on a nature walk or hike, keep your eyes peeled for the perfect rock that will inspire your next creation. You never know where your creativity will take you. Happy crafting!

Certified 4-Blade Oil Well Drilling PDC Bit for Improved Efficiency and Durability

Title: Mastering Efficiency and Precision: API-Certified 4-Blade Oil Well Drilling PDC BitIntroduction:As the global demand for oil continues to rise, the petroleum industry is constantly searching for advanced drilling technologies that ensure optimal efficiency and precision. One notable breakthrough comes in the form of the 4-blade oil well drilling diamond matrix body PDC bit with an API certificate. Manufactured by reliable suppliers such as Urumqi Siruite Mechanical Equipment Co., Ltd., this cutting-edge PDC bit is revolutionizing the oil drilling landscape. In this blog, we delve into the remarkable features and advantages of this API-certified PDC bit, showcasing its role in maximizing operational outcomes in oil exploration and extraction.1. Understanding the API Certification for PDC Bits:The American Petroleum Institute (API) serves as the international benchmark for oil and gas equipment standards. When a PDC bit receives API certification, it signifies that the tool has met rigorous quality and performance criteria set by the industry. This certification serves as a testament to the PDC bit's reliability, efficiency, and safety, instilling confidence in drillers worldwide.2. Unveiling the Features of the 4-Blade Oil Well Drilling PDC Bit:2.1 Diamond Matrix Body:The diamond matrix body of this advanced PDC bit provides exceptional durability and wear resistance, ensuring a longer lifespan and reduced tool replacement costs. The strategically formulated diamond matrix also enhances heat resistance, enabling the bit to withstand high-temperature drilling environments with ease.2.2 Four-Blade Design:The four-blade configuration of this PDC bit enhances cutting efficiency and stability during drilling operations. With each blade responsible for a specific portion of the bit's cutting surface, load distribution is optimized, resulting in reduced vibration and increased control. This unique design also enhances the cutting action, minimizing torque and drag, thereby optimizing overall drilling performance.2.3 Advanced PDC Cutter Technology:The PDC cutters incorporated into this bit are constructed using state-of-the-art technology, making them incredibly robust and efficient. These cutters can handle even the most abrasive formations, ensuring efficient and precise drilling while maintaining edge quality. Their extended lifespan reduces the frequency of tool replacements, saving time and money.3. Advantages of the 4-Blade Oil Well Drilling PDC Bit:3.1 Increased Drilling Efficiency:With enhanced cutting action and optimized load distribution, this PDC bit enables operators to achieve higher drilling speeds, ultimately reducing well construction time and costs. The reduced number of trips required to complete a well minimizes downtime, improving overall drilling productivity.3.2 Improved Durability and Reliability:The diamond matrix body, coupled with the advanced PDC cutter technology, significantly extends the lifespan of this PDC bit. Its resistance to wear and heat makes it suitable for long-duration drilling operations without compromising performance.3.3 Superior Control and Precision:The unique four-blade design minimizes the risk of deviation, ensuring the bit stays on track, even in challenging formations. This feature allows for accurate wellbore placement, thereby maximizing hydrocarbon recovery and reducing the need for re-drilling.4. API PDC Drilling for Future Success:The API-certified 4-blade oil well drilling PDC bit serves as a game-changer for the petroleum industry. Its adherence to API standards ensures industry-wide compatibility and promotes seamless integration with existing drilling equipment and workflows. By embracing this technological advancement, drilling operations can greatly improve efficiency, precision, and operational outcomes.Conclusion:The 4-blade oil well drilling diamond matrix body PDC bit with an API certificate stands at the forefront of optimizing oil drilling processes. Offering exceptional cutting efficiency, durability, and precision, this advanced tool streamlines drilling operations, reduces costs, and enhances overall productivity. By harnessing these cutting-edge capabilities, oil exploration and extraction activities can progress with greater success on a global scale. Embrace the future of oil well drilling with the API-certified 4-blade PDC bit for unmatched performance and unparalleled results.

Boost Your Drilling Efficiency with Premium PDC Button Bits

Title: Innovative PDC Button Bits Revolutionize the Mining IndustryIntroduction:In the ever-evolving mining industry, technological advancements play a crucial role in enhancing efficiency and productivity. One of the recent game-changing innovations in drilling equipment is the PDC button bits. Manufactured by {Company Name}, these cutting-edge tools have garnered considerable attention and acclaim for their exceptional performance and durability. Let's delve into the fascinating world of PDC button bits and explore how they are revolutionizing the mining sector.1. Understanding PDC Button Bits:PDC, acronym for Polycrystalline Diamond Compact, refers to a revolutionary synthetic diamond material that surpasses traditional materials in terms of hardness and wear resistance. PDC button bits, fitted with these diamonds, serve as the primary cutting component in drilling equipment. Their innovative design and exceptional durability make them highly sought after in the mining industry.2. Enhanced Performance and Durability:Compared to conventional button bits, PDC button bits offer numerous advantages. Firstly, their superior cutting ability significantly reduces drilling time, allowing mining operations to proceed at a faster pace. Secondly, the enhanced durability of PDC button bits ensures prolonged usage and minimizes downtime for maintenance or bit replacement.Furthermore, traditional button bits are prone to wear and tear due to the repetitive impact on hard surfaces. PDC button bits, on the other hand, are designed to withstand these high-impact conditions, resulting in improved performance and a longer lifespan. This ensures cost-effective and uninterrupted drilling, making them a preferred choice for mining companies worldwide.3. Innovative Design Features:{Company Name}'s PDC button bits boast several unique design features that set them apart from their competitors. These bits are crafted using the latest engineering techniques, ensuring stability and precision during drilling operations. Additionally, their geometrically optimized designs maximize cutting efficiency, minimizing energy consumption and increasing overall productivity.Furthermore, {Company Name} incorporates advanced manufacturing processes to ensure the integrity and reliability of their PDC button bits. Rigorous quality control checks and tests guarantee that each product meets the highest industry standards, instilling confidence in mining companies relying on these bits for their operations.4. Wide Range of Applications:The versatility of PDC button bits expands their applications beyond traditional mining activities. These bits are suitable for drilling in a variety of challenging geological formations, including hard rock, shale, limestone, sandstone, and more. Their adaptability and effectiveness make PDC button bits a preferred choice for industries such as oil and gas exploration, construction, and geothermal drilling.5. Promoting Sustainable Mining Practices:In addition to their exceptional performance, PDC button bits contribute to sustainable mining practices. The reduced drilling time achieved with these bits reduces the carbon footprint of mining operations. Furthermore, the extended lifespan of PDC button bits reduces the need for frequent replacements, resulting in reduced waste generation.Conclusion:The introduction of PDC button bits has marked a significant milestone in the mining industry's pursuit of enhanced efficiency and sustainability. The unrivaled performance, durability, and application versatility of these bits have revolutionized drilling operations globally. As {Company Name} continues to innovate and refine its PDC button bits, mining companies can expect even greater advancements in the future.