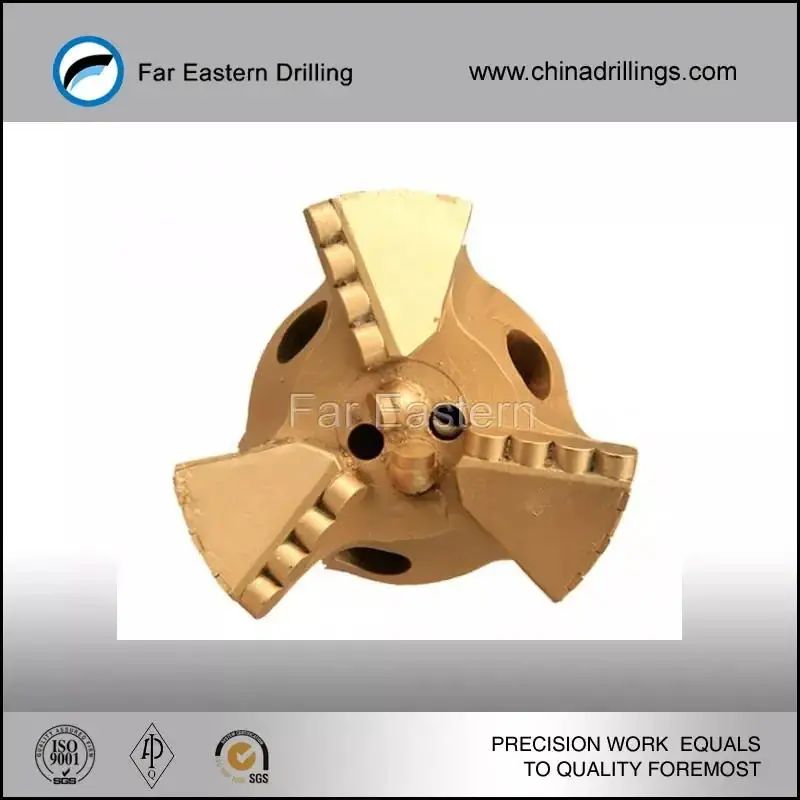

High Quality 120mm Tricone Roller Cone for Sale

By:Admin

The 120mm tricone roller cone is engineered with precision and advanced technology to deliver exceptional results in the field. Its robust construction and durable materials make it suitable for the most demanding drilling conditions, providing superior resistance to wear and tear. With its excellent performance capabilities, this roller cone is designed to meet the needs of the oil and gas, mining, and construction industries, where reliability and efficiency are crucial for success.

One of the key features of the 120mm tricone roller cone is its highly efficient cutting structure, which allows for fast and smooth drilling operations. The roller cone is equipped with high-quality bearings and seals, ensuring reliable performance and longevity. Furthermore, it is designed to deliver excellent stability and balance during drilling, reducing the risk of deviation and increasing accuracy.

Company X has a long-standing reputation for producing high-quality drilling equipment, and the release of the 120mm tricone roller cone further solidifies their position as an industry leader. With a strong focus on innovation and customer satisfaction, the company is committed to delivering products that meet the highest standards of quality and performance. Their team of experts and engineers continuously work to develop cutting-edge solutions that address the evolving needs of the drilling industry.

In addition to the 120mm tricone roller cone, Company X offers a wide range of drilling equipment, including drill bits, reamers, and drilling accessories. Their comprehensive product line caters to various drilling applications and is trusted by drilling professionals around the world. With a global presence and a network of distributors, the company is able to provide reliable support and timely solutions to customers across different regions.

As part of their commitment to quality and customer satisfaction, Company X conducts rigorous testing and quality control measures to ensure that their products meet the highest standards. The 120mm tricone roller cone undergoes thorough inspection and performance testing to guarantee its reliability and durability in the field. This dedication to excellence has earned the company the trust and loyalty of their customers, who rely on their products to achieve optimal results in their drilling operations.

The release of the 120mm tricone roller cone is a testament to Company X's dedication to continuous improvement and innovation. By addressing the specific needs and challenges of the drilling industry, the company remains at the forefront of technological advancements, offering solutions that drive efficiency and productivity. As the demand for reliable and high-performance drilling equipment continues to grow, Company X is well-positioned to meet the needs of the industry and deliver exceptional value to their customers.

In conclusion, the release of the 120mm tricone roller cone reaffirms Company X's commitment to excellence and innovation in the drilling equipment industry. With its advanced design, superior performance, and reliability, this new product is set to make a significant impact on drilling operations worldwide. As the company continues to push the boundaries of technological advancement, customers can expect to benefit from a wide range of cutting-edge solutions that meet their drilling needs. Company X remains dedicated to providing the highest quality products and exceptional service, solidifying their position as a trusted partner in the industry.