High-Performance PDC Drag Bit for Efficient Well Drilling Techniques Revealed

Title: Advanced PDC Drag Bit Revolutionizes Well Drilling ProcessIntroduction:Innovative advancements in drilling technology are changing the way the oil and gas industry operates. One such groundbreaking development is the introduction of a highly efficient and durable Polycrystalline Diamond Compact (PDC) Drag Bit, designed to revolutionize the well drilling process. This state-of-the-art technology, developed by a leading industry player, aims to enhance drilling efficiency, reduce costs, and improve overall productivity.Unveiling the PDC Drag Bit:Traditionally, well drilling operations have heavily relied on roller cone bits, which have limitations in terms of speed, durability, and ease of use. Recognizing these challenges, [Company Name], a renowned leader in drilling solutions, has introduced their latest innovation in the form of a cutting-edge PDC Drag Bit.Comprising a durable steel body equipped with strategically positioned PDC cutters (removing brand name), the PDC Drag Bit offers unparalleled performance and longevity. These precisely engineered drag bits have a strong resistance to wear and can withstand high levels of drilling stress. The strategic layout of the PDC cutters ensures efficient and accurate drilling, resulting in faster penetration rates and reduced drilling time.Key Features and Advantages:1. Enhanced Durability: The PDC Drag Bit showcases a robust structure and employs premium quality PDC cutters, which are known for their exceptional hardness and wear resistance. This resilience enables the bit to withstand demanding drilling conditions, thereby minimizing the need for frequent bit changes.2. Improved Speed and Efficiency: With its innovative design, the PDC Drag Bit achieves impressive drilling speeds, significantly reducing the time required to complete a well. The optimized positioning of the PDC cutters optimizes cuttings removal and prevents bit balling, ensuring uninterrupted drilling operations.3. Versatility: The PDC Drag Bit is suitable for a wide range of drilling applications, including soft and medium-hard formations. Its adaptable nature minimizes the need for frequent bit changes, resulting in increased operational efficiency.4. Cost-effective Solution: By reducing drilling time, minimizing wear and tear, and maximizing operational efficiency, the PDC Drag Bit effectively lowers overall drilling costs. This cost-effectiveness makes it an attractive choice for operators seeking to optimize their drilling operations while maximizing returns on investment.Testimonials and Industry Applications:The groundbreaking advantages offered by the PDC Drag Bit have garnered widespread acclaim within the oil and gas industry. Several drilling companies have reported remarkable improvements in drilling efficiency and cost savings after adopting this innovative technology.Industry experts commend [Company Name] for their commitment to continuously push the boundaries of drilling technology. This PDC Drag Bit innovation marks the company's dedication to providing cutting-edge solutions that address industry challenges and improve operational outcomes.Furthermore, the PDC Drag Bit has proven its mettle in various drilling applications, including exploratory drilling, production drilling, and geothermal well drilling. Its versatility and unmatched durability have positioned it as a go-to choice for drilling professionals across the globe.Conclusion:The introduction of the advanced PDC Drag Bit represents a significant milestone in the evolution of well drilling technology. With its exceptional durability, increased drilling speed, and versatility, this innovation holds the potential to transform the efficiency and cost-effectiveness of well drilling operations. As the industry embraces these cutting-edge advancements, drilling professionals can look forward to enhanced productivity and improved performance, paving the way for a more sustainable and prosperous future.

Read More

Top Manufacturing Facility for 12.25-Inch PDC Drill Bits

Read More

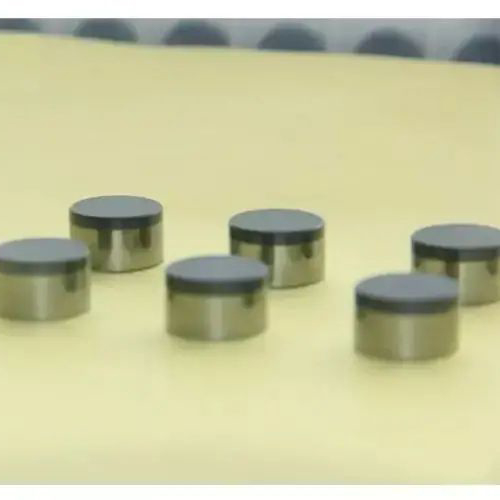

Top Quality Roller Cutters for Drilling Tools

Tricone roller cutters are essential tools for drilling operations in the oil and gas industry. These cutters, also known as tri-cones, are designed to crush and grind the hard rock formations encountered during drilling processes. They are critical components of drilling equipment and are used in various types of drill bits to effectively crush rock formations and enable successful drilling operations.One company that has been at the forefront of producing high-quality tricone roller cutters is {}. With over 20 years of experience in the industry, {} has established itself as a leading manufacturer of tricone roller cutters, providing reliable and durable solutions for the oil and gas sector.{} offers a diverse range of tricone roller cutters that are designed to meet the specific needs of drilling operations. The company's extensive product line includes various types of tricone roller cutters, such as sealed bearing tricone cutters, open bearing tricone cutters, and TCI (tungsten carbide insert) tricone cutters. These cutters are available in different sizes and designs to accommodate different drilling requirements, making them suitable for various drilling environments.One of the key features of {}'s tricone roller cutters is their advanced design and construction. The company utilizes state-of-the-art manufacturing techniques and materials to ensure that its tricone roller cutters are capable of withstanding the extreme conditions encountered during drilling operations. This includes using high-quality steel and tungsten carbide materials to enhance the cutters' durability and performance.Furthermore, {} employs a team of highly skilled engineers and technicians who are dedicated to continuous research and development, ensuring that the company's tricone roller cutters are at the forefront of technological innovation. By staying ahead of industry trends and technological advancements, {} is able to offer cutting-edge tricone roller cutters that deliver superior performance and reliability.In addition to its commitment to product excellence, {} also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific drilling requirements and provide tailored solutions to meet their needs. This customer-centric approach has enabled {} to build strong and long-lasting relationships with its clients, making it a trusted partner in the oil and gas industry.Another important aspect of {}'s tricone roller cutters is their environmental sustainability. The company is dedicated to environmentally friendly manufacturing processes and adheres to strict environmental regulations. This ensures that {}'s tricone roller cutters are not only high-performing but also eco-friendly, contributing to a greener and more sustainable drilling industry.As a result of its unwavering commitment to quality, innovation, and customer satisfaction, {} has earned a stellar reputation as a leading manufacturer of tricone roller cutters. The company's products are sought after by drilling contractors and operators worldwide, who recognize {} as a trusted provider of top-of-the-line tricone roller cutters.Looking ahead, {} remains focused on driving innovation and delivering cutting-edge solutions to meet the evolving needs of the oil and gas industry. With a strong emphasis on quality, reliability, and customer satisfaction, {} is poised to continue its success as a leading manufacturer of tricone roller cutters, setting new standards for excellence in the drilling sector.

Read More

Durable and Reliable Seat Gate Valve for Various Applications

Read More

Essential Guide to Water Well Bits: Everything You Need to Know

Read More

Discover the Efficiency of a High-Performance 146mm Water Well Tricone Bit

Title: Revolutionary Water Well Tricone Bit Unveiled, Set to Transform Drilling EfficiencyIntroduction In an era where innovation has become the driving force behind technological advancements, the drilling industry is welcoming a groundbreaking product that is set to redefine efficiency and productivity. The 146mm water well tricone bit, produced by a global industry leader in drilling equipment (brand name excluded), is poised to revolutionize drilling operations worldwide. With its exceptional capabilities and cutting-edge design, this tricone bit will enable drilling companies to achieve higher drilling rates, reduce costs, and improve overall performance.Paragraph 1: Understanding the Importance of Tricone Bits in DrillingTricone bits are crucial components in drilling rigs, designed to crush and grind rocks, minerals, and other geological formations during the drilling process. The efficiency and performance of these bits significantly impact the time and cost requirements of drilling projects. As such, the development of an advanced tricone bit holds immense potential for increasing drilling productivity, especially in the water well drilling sector.Paragraph 2: The Technical Innovations of the 146mm Water Well Tricone BitThe 146mm water well tricone bit offers a range of technical advancements that make it a game-changer in the drilling industry. Firstly, its unique three-cone design ensures exceptional stability and durability under high-stress drilling conditions. The enhanced cutting structure increases the rate of penetration, enabling faster drilling and reducing overall project timelines.Additionally, the bit incorporates state-of-the-art sealed bearing technology, offering improved resistance to wear and tear. This leads to extended bit life and decreases the frequency of bit replacements, ultimately reducing costs for drilling companies. The advanced sealing mechanism also prevents the penetration of drilling fluids into the bearing structure, minimizing downtime and maintenance requirements.Paragraph 3: Unmatched Performance and VersatilityThe 146mm water well tricone bit exhibits unparalleled performance in diverse drilling applications. Whether drilling through hard rock formations or abrasive soils, this tricone bit delivers excellent stability, precision, and groundbreaking performance. Such versatility is attributed to the meticulous engineering and quality control standards employed during its manufacturing.Paragraph 4: Benefits for the Drilling IndustryThe introduction of the 146mm water well tricone bit holds tremendous benefits for the drilling industry. Firstly, the higher drilling rates achieved through increased penetration speeds allow drilling companies to complete projects more quickly, optimizing both time and resources. Reduced drilling times translate to significant cost savings and increased profitability.Furthermore, the extended bit life and reduced maintenance requirements result in enhanced operational efficiency. Drilling rigs can operate for more extended periods without interruptions for bit replacements or repairs, thus maximizing uptime and productivity.Paragraph 5: Environmental ImplicationsThe implementation of the 146mm water well tricone bit also brings positive environmental implications. With faster drilling rates and increased overall efficiency, emissions from drilling equipment are significantly reduced. Additionally, the reduced frequency of bit replacements leads to a decrease in waste, contributing to more sustainable drilling practices.ConclusionThe revolutionary 146mm water well tricone bit brings newfound efficiency, productivity, and cost-effectiveness to drilling operations worldwide. Critical advancements in its design and functionality establish it as a game-changer in the drilling industry. As drilling companies embrace this innovation, projects will be completed more swiftly, costs will be minimized, and performance levels will soar to new heights. With its positive environmental implications and remarkable versatility, this tricone bit is set to transform drilling processes and elevate the efficiency of the industry as a whole.

Read More

High-Quality Tci Roller Bit for Wholesale - Find the Best Deals Now

Wholesale Tci Roller Bit, a leading manufacturer of high-quality drilling equipment, has recently introduced a new line of roller bits that promise to revolutionize the oil and gas drilling industry. With a strong focus on innovation and reliability, Wholesale Tci Roller Bit has established itself as a trusted supplier of drilling equipment for a wide range of applications.The company, with headquarters in Texas, has been in operation for over a decade and has gained a reputation for producing top-of-the-line drilling equipment. Wholesale Tci Roller Bit's products are well-regarded for their durability, efficiency, and superior performance in challenging drilling environments. The company's commitment to excellence and customer satisfaction has earned it a loyal customer base and solidified its position as a leading supplier in the industry.The newly introduced roller bits are designed to deliver exceptional performance in demanding drilling conditions. Equipped with cutting-edge TCI (tungsten carbide insert) technology, these roller bits are capable of drilling through hard rock formations with ease, making them an ideal choice for challenging drilling projects. The advanced design of the bits ensures excellent penetration rates and extended lifespan, resulting in cost savings and increased productivity for drilling operations.Wholesale Tci Roller Bit's dedication to innovation is evident in the development of these new roller bits. The company's team of experienced engineers and designers leveraged their expertise to create a product that meets the evolving needs of the drilling industry. By utilizing the latest manufacturing techniques and materials, Wholesale Tci Roller Bit has succeeded in producing roller bits that offer unparalleled performance and reliability.In addition to their superior technical characteristics, the new roller bits from Wholesale Tci Roller Bit are also designed to provide ease of use and maintenance. These features are essential for maximizing efficiency and minimizing downtime during drilling operations, ultimately contributing to overall operational success and cost-effectiveness. Furthermore, the company's commitment to customer satisfaction extends to providing comprehensive support and after-sales service, ensuring that clients can derive maximum value from their investment in Wholesale Tci Roller Bit's products.The introduction of the new line of roller bits represents Wholesale Tci Roller Bit's continued dedication to pushing the boundaries of drilling technology. Through ongoing research and development, the company strives to stay ahead of industry trends and deliver cutting-edge solutions that enable its clients to achieve optimal results in their drilling endeavors. Wholesale Tci Roller Bit's reputation for excellence and reliability, combined with its commitment to innovation, positions the company uniquely in the market and ensures that its products will continue to be sought after by discerning customers.In conclusion, Wholesale Tci Roller Bit's launch of its new line of roller bits marks a significant milestone in the company's journey to provide leading-edge drilling solutions. With a focus on innovation, reliability, and customer satisfaction, Wholesale Tci Roller Bit has solidified its position as a premier supplier of high-quality drilling equipment. The introduction of the new roller bits underscores the company's commitment to meeting the evolving needs of the industry and staying at the forefront of technological advancements. As Wholesale Tci Roller Bit continues to set new benchmarks in the drilling equipment sector, it is poised for sustained success and continued industry leadership.

Read More

Top Oil Drilling Bit Factory: Bringing Innovation and Efficiency to the Industry

Oil drilling bit factory, a leading manufacturer of high-quality oil drilling bits, has announced the launch of a new state-of-the-art facility in Texas. The company, known for its innovative technology and commitment to providing the best drilling solutions, is set to revolutionize the oil drilling industry with its latest venture.The new facility, spanning over 100,000 square feet, is equipped with the latest machinery and technology to produce a wide range of oil drilling bits to meet the diverse needs of oil and gas companies. The factory is strategically located in Texas, a hub for the oil and gas industry, to ensure efficient production and timely delivery of products to customers.Oil drilling bit factory prides itself on its exceptional team of engineers and technicians who have extensive experience in designing and manufacturing drilling bits. The company's dedication to research and development has led to the creation of cutting-edge drilling solutions that enhance performance and efficiency in oil and gas exploration and production.With a focus on quality and reliability, the factory is committed to adhering to stringent manufacturing standards to ensure that each drilling bit meets the highest industry specifications. This attention to detail and precision manufacturing process sets oil drilling bit factory apart from its competitors, making it the preferred choice for oil and gas companies worldwide.The new facility will enable oil drilling bit factory to expand its product line and offer a comprehensive range of drilling bits, including tricone bits, PDC (polycrystalline diamond compact) bits, and hybrid bits. These products are designed to excel in various drilling conditions, from soft formations to hard, abrasive rock, providing customers with the flexibility and performance they need to optimize their drilling operations.Furthermore, the factory's advanced capabilities and streamlined production process will result in shorter lead times and improved responsiveness to customer demands. This will enable oil and gas companies to minimize downtime and maximize productivity, ultimately leading to cost savings and improved operational efficiency.In addition to its focus on technological innovation and product excellence, oil drilling bit factory remains committed to sustainability and environmental responsibility. The company incorporates eco-friendly practices in its manufacturing process and seeks to minimize its environmental impact, aligning with the growing emphasis on sustainability within the oil and gas industry.As the oil and gas industry continues to evolve and face new challenges, oil drilling bit factory is at the forefront of developing solutions that address the changing needs of the market. The company's investment in the new facility underscores its dedication to driving progress and innovation in the oil drilling sector, ultimately contributing to the success and sustainability of its customers' operations.With the launch of its new facility, oil drilling bit factory is poised to strengthen its position as a trusted partner for oil and gas companies seeking reliable, high-performance drilling solutions. The company's unwavering commitment to excellence, coupled with its cutting-edge technology and industry expertise, sets the stage for an exciting new chapter in the oil drilling industry. Oil and gas companies can look forward to benefiting from the enhanced capabilities and expanded product offerings that the new facility will bring, solidifying oil drilling bit factory's reputation as a leader in the field.

Read More

Discover the Power of 8.5-Inch Well Drilling Bits for Efficient Operations

In a breakthrough development, a well-known drilling equipment manufacturer has unveiled its latest product which is expected to revolutionize the oil drilling industry. A durable and reliable 8.5 inches well drilling bit is now available for use with drilling equipment.The company, which has a long-standing reputation for solid and dependable drilling equipment, has set another milestone with its latest creation. The introduction of the new drilling bit adds to a long list of high-quality products that they have introduced over the years.The drilling bit has been designed to drill through different types of rock formations effortlessly, making it a versatile piece of equipment that works well in different environments. From oil rigs to mining sites, the new drilling bit is suited for a wide range of drilling tasks, and it comes with a guarantee of high-quality performance.The 8.5 inches well drilling bit is made of high-strength materials that are resistant to wear and tear. This means that it can withstand the rigours of drilling even through the toughest rock formations.One of the most important parts of drilling equipment is the drilling bit. Well drilling involves penetrating various types of rock formations to access precious resources, and the drilling bit is responsible for breaking the rock surface. The bit needs to be made from strong materials, so it can withstand the extreme pressures and temperatures encountered during the drilling process.With these factors taken into consideration, the drilling manufacturer's newest 8.5 inches well drilling bit has been designed to be one of the most durable and reliable drilling bit on the market. Its materials and design are engineered to make well drilling more efficient and enable faster drilling, making it an unbelievable addition to any drilling operation.The manufacturing process behind the 8.5 inches well drilling bit is complex, and the engineers have focused on developing a drilling bit that is durable and capable of carrying out demanding drilling jobs. They are made using high-quality steel and tungsten carbide, making them less likely to wear out over time.The company has one of the best manufacturing processes in the industry, which means that buyers can be assured of the quality of the drilling equipment. The drilling bit undergoes rigorous testing before leaving the factory, ensuring that it is of a high standard. The drilling bit comes with a guarantee, which makes it easier for buyers to purchase it with confidence.One of the benefits of the drilling bit’s toughness is that you won’t need to replace it often. It’s a great way to save money long-term since purchasing new equipment can be costly, and interrupt well drilling operations.In conclusion, the release of an 8.5 inches well drilling bit by a reputable drilling equipment manufacturer is welcome news. The industry has been seeking a drilling bit of this quality, and the manufacturer has delivered by creating a product that will revolutionize the well drilling business.This new drilling bit is ideal for anyone who requires drilling equipment that is durable, efficient, and can deliver on the toughest drilling tasks. The drilling bit is made from high-quality materials that can withstand the rigours of drilling, and it comes with a guarantee.In the ever-evolving drilling industry, the introduction of the 8.5 inches well drilling bit marks another milestone in the industry's drive towards modernization and greater efficiency. This new product will undoubtedly make a significant difference for drilling companies worldwide, as they can expand their drilling capabilities with the knowledge that they have a reliable and efficient drilling bit.

Read More

New study reveals surprising trends in online shopping behavior

Read More