120mm Bit Factory Excels in IADC517 Technology Implementation" can be rewritten as "Experts in IADC517 Technology: 120mm Bit Factory Achieves Remarkable Success" without mentioning the brand name.

Title: IADC517 120mm Bit Factory Sets New Industry StandardsIntroduction:In an ever-evolving oil and gas industry, technological advancements continue to drive the global market forward. One company at the forefront of this progress is a renowned bit manufacturer, known for consistently delivering high-performance products. Their new IADC517 120mm bit factory has recently revolutionized the industry, offering a cutting-edge solution for drilling operations worldwide.Unleashing Unparalleled Performance:The introduction of the IADC517 120mm bit factory by this leading manufacturer marks a major milestone in the drilling industry. With years of expertise in bit manufacturing, the company has successfully developed a state-of-the-art facility that combines cutting-edge technology with unparalleled expertise.The IADC517 120mm bit factory aims to set new standards by delivering outstanding performance, durability, and efficiency to drilling professionals. It harnesses the latest advancements in materials, design, and manufacturing processes, guaranteeing exceptional results even in the most challenging drilling conditions.Advanced Design and Manufacturing:This factory incorporates advanced design techniques to optimize drilling efficiency and productivity. By utilizing advanced CAD/CAM software, engineers have created a bit design that maximizes axial load capacity and ensures better guidance in the wellbore. Additionally, extensive simulation and testing have been carried out to enhance durability and longevity under extreme drilling conditions.The manufacturing process at the IADC517 120mm bit factory adheres to strict quality control measures to ensure every product meets the highest industry standards. State-of-the-art machinery and automated processes streamline production, reducing human error and increasing output. Stringent testing procedures are implemented at various stages, guaranteeing durability and reliability for every bit produced.Commitment to Sustainable Solutions:Alongside its focus on performance, the manufacturer is dedicated to sustainable practices throughout the production process. The IADC517 120mm bit factory utilizes energy-efficient machinery and optimized production techniques to minimize its environmental impact. Furthermore, the company promotes responsible waste management, ensuring that materials are recycled or disposed of safely.Global Impact:The introduction of the IADC517 120mm bit factory has already had a significant impact on the global drilling industry. Drilling professionals worldwide now have access to this advanced cutting tool that offers improved performance and productivity. The factory's production capacity ensures a steady supply of bits to meet growing market demands, contributing to the overall efficiency and success of drilling operations globally.Collaboration and Customer Satisfaction:The company's commitment to customer satisfaction lies at the core of its operations. The IADC517 120mm bit factory has fostered a collaborative relationship with drilling professionals, actively seeking feedback and incorporating it into future product developments. Through effective communication channels, the manufacturer has built a reputation for addressing customer needs and delivering tailored solutions that enhance drilling operations.Looking Forward:As the IADC517 120mm bit factory paves the way for drilling advancements, the manufacturer continues its research and development efforts to push the boundaries further. Collaboration with industry experts, drilling professionals, and academia ensures that the factory remains at the forefront of innovation. Moreover, the company's commitment to sustainable practices aligns with the global industry's increasing focus on environmentally conscious solutions.Conclusion:The emergence of the IADC517 120mm bit factory has established a new benchmark in the drilling industry. With its advanced design, precise manufacturing processes, and commitment to sustainability, this innovative facility has proven pivotal in meeting the evolving demands of the oil and gas sector. As drilling professionals continue to seek cutting-edge solutions, the IADC517 120mm bit factory remains a trailblazer, driving the industry forward with its unmatched performance, reliability, and customer satisfaction.

Read More

Canadian Gold Exploration Company to Conduct Exploration Program at Eau Claire Site

to Make Your Core Cutting Job Easier with Hard Rock Core Cutters from Fury Gold MinesFury Gold Mines, a Canadian-focused gold exploration company, is proud to provide high-quality hard rock core cutters that are designed to make your core cutting job easier and more efficient. With our commitment to safety, governance, and business standards, you can trust our products to deliver top-notch performance and reliability, every time.Our hard rock core cutters are built to handle the toughest drilling applications in the mining industry. From dense granite to hard quartzite, our core cutters are designed to provide precise and accurate results, while reducing the amount of wear and tear on your equipment. Whether you're working in a remote location or a busy mining site, our tools are designed to keep up with the demands of your operation.One of the key benefits of our hard rock core cutters is their durability. Made from premium quality materials, our core cutters are built to withstand the toughest conditions, including extreme heat, moisture, and heavy use. With our tools, you can be confident that you're getting high-quality results, even in the most challenging drilling environments.In addition to their durability, our core cutters are also designed for ease of use. Our tools feature ergonomic designs that are easy to handle, even in tight spaces. Whether you're working on a long-term drilling project or a quick site evaluation, our core cutters are designed to help you get the job done quickly and efficiently.Another advantage of our hard rock core cutters is their versatility. Our tools are designed to work with a wide range of equipment, including hand-held drills, drill rigs, and other heavy machinery. With our core cutters, you can be confident that you're getting the flexibility you need to tackle any job, no matter how complex.At Fury Gold Mines, we are committed to providing our customers with the highest quality products and services. Our hard rock core cutters are just one example of our commitment to excellence. When you choose Fury, you can be confident that you're getting the best in the business. With our tools, you can be sure that your drilling project will be a success. So why wait? Contact us today to learn more about our hard rock core cutters and how they can help you with your next drilling project.

Read More

Unveiling the Key Benefits of Double Offset Butterfly Valves

Title: Innovative Double Offset Butterfly Valve Revolutionizes Industrial ApplicationsIntroduction:In today's highly competitive industrial landscape, companies are constantly seeking technological advancements to enhance their efficiency and productivity. One such breakthrough innovation in valve technology is the Double Offset Butterfly Valve (DOBV). Manufactured by a renowned valve manufacturer (), this cutting-edge valve design is set to revolutionize various industrial applications.Section 1: Understanding the Double Offset Butterfly Valve (150 words)The Double Offset Butterfly Valve is a specialized valve that offers precise and reliable control over the flow of various substances, including liquids and gases. Its unique design comprises a disc and a shaft, which are eccentrically mounted, allowing for improved sealing capabilities and reduced operating torque. Unlike traditional butterfly valves, the double offset design ensures a bubble-tight seal even in high-pressure applications, making it ideal for industries such as oil and gas, chemical processing, water treatment, and power generation.Section 2: Key Features and Benefits (200 words)2.1 Advanced Sealing Mechanism: The DOBV utilizes a two-step sealing mechanism that maximizes tightness and minimizes leakage. The eccentric mounting of the disc ensures contact only at the final closed position, reducing valve wear and extending its lifespan.2.2 Reduced Torque: The double offset design decreases the friction between the disc and the seat, resulting in significantly reduced operating torque requirements. This enhances the valve's efficiency and reduces operational costs over time, making it an energy-efficient solution for industrial applications.2.3 Increased Durability: Crafted from high-quality materials such as stainless steel, carbon steel, or exotic alloys, the DOBV offers exceptional resistance to corrosion, wear, and erosion. This ensures a long-lasting and reliable performance, even in demanding environments.2.4 Versatile Operation: The DOBV can be operated manually, pneumatic, electrically, or mechanically, offering users flexibility and convenience based on their specific application requirements.2.5 Enhanced Control: With its precise throttling and control abilities, the DOBV provides exceptional flow regulation, allowing companies to optimize their processes and maintain optimal operational conditions.Section 3: Applications and Industries (200 words)Double Offset Butterfly Valves find applications in various industries, including but not limited to:3.1 Oil and Gas: The DOBV is employed in oil refineries, pipelines, offshore platforms, and storage terminals, where it ensures reliable and safe regulation of crude oil, natural gas, and other hydrocarbon-based fluids.3.2 Chemical Processing: In chemical plants, the DOBV aids in controlling the flow of aggressive and corrosive chemicals, ensuring the safety of equipment, personnel, and the environment.3.3 Water Treatment: Municipal water treatment facilities use the DOBV for precise flow control of water throughout the treatment process, ensuring quality control and efficient operation.3.4 Power Generation: The DOBV is utilized in power plants to regulate the flow of water, steam, and other fluids, contributing to efficient electricity generation.3.5 HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, the DOBV provides precise temperature and pressure control, resulting in improved energy efficiency.Section 4: Conclusion (100 words)The Double Offset Butterfly Valve represents a significant technological advancement in valve design, offering numerous benefits, including advanced sealing, reduced torque requirements, enhanced durability, and versatile operation. Its ability to provide precise flow control makes it a desirable choice across industries such as oil and gas, chemical processing, water treatment, power generation, and HVAC systems. Embracing this innovative valve not only ensures optimal operational performance but also contributes to enhanced safety, reduced maintenance costs, and improved overall efficiency.

Read More

Top-Quality Tricone Drill Bit Ideal for Oil and Gas Exploration Available in Ogden, UT - Browse Now on KSL Classifieds

Tricone Drilling Bits - Your Ultimate Partner for Oil & Gas DrillingThe oil and gas industry is a highly competitive and lucrative field, where success is only achieved through the proper utilization of top-grade equipment and technology. One of the most pivotal pieces of equipment that are integral to the drilling process is the Tricone drilling bit. Combining the latest technology and advanced engineering, these bits are designed to extract oil and gas from deep beneath the surface. At [removed brand name], we offer high-quality tricone drilling bits that are designed to withstand the toughest drilling conditions. Our tricone bits are crafted with high-quality tungsten carbide inserts and premium-grade steel, ensuring maximum performance, durability, and longer bit life. Used in various drilling applications, our tricone bits are available in different sizes and configurations, including the widely popular 118mm tricone drilling bit. Our tricone bits are highly versatile and can be used for drilling in various rock formations, such as hard-rock formations, soft-rock formations, and even mixed formations. The 118mm tricone drilling bit is used extensively in oil and gas drilling due to its excellent performance and specifications. It features three cones, each with tungsten carbide inserts, that combine to create a dynamic cutting structure. The design of its gage row also ensures continuous drilling and prevents the bits from deviating from its intended path while drilling. The versatility of these tricone drilling bits does not stop with their unique design and features. They can be used on various drill rigs, ranging from small and portable rigs to large and robust rigs, depending on the project requirements. These tricone bits are also available with various connection types, such as API connections, ensuring that they can fit into any drill rig or setup. Our tricone drilling bits are designed to handle the harshest drilling environments, making them the first choice for professionals in the oil and gas industry. All our bits undergo extensive testing to ensure that they can deliver maximum performance, long bit life, and reliability. In conclusion, if you are looking for high-quality tricone drilling bits for your oil and gas drilling projects, then [removed brand name] has got you covered. Our tricone drilling bits are some of the best in the market, delivering maximum performance and durability in the most demanding environments. Our 118mm tricone drilling bit is one of our most popular bits, with proven performance and reliability in various drilling conditions. Contact us today to learn more about our tricone drilling bits and how they can help you achieve your drilling objectives. Keywords: tricone drilling bits, 118mm, oil and gas drilling, tungsten carbide inserts, dynamic cutting structure, API connections, durable, reliable, long bit life.

Read More

Top-Quality Matrix Body PDC Bits with IADC Code for Efficient Drilling Operations

PDC Bits: The Ultimate Solution for Efficient Drilling OperationsWhen it comes to drilling operations, the quality of the drill bit used determines the efficiency of the process. With the increasing demand for hydrocarbons and minerals, there is a need for high-performance drilling solutions that can handle different formations and conditions. This is where PDC (Polycrystalline Diamond Compact) drill bits come in.PDC bits are designed to provide efficient penetration rates, longer bit life, and reduced downtime during drilling operations. The technology behind PDC bits involves layering polycrystalline diamond onto a tungsten carbide substrate, creating a super-hard and wear-resistant cutting surface.Besides, PDC bits are engineered to withstand high torque, high temperatures, and abrasive formations, making them suitable for a wide range of drilling applications. Whether drilling in hard rock, shale, sandstone, or clay, PDC bits deliver exceptional performance and improved drilling economics.Features of PDC Bits1. Matrix body PDC bitsMatrix body PDC bits are designed with a tungsten carbide matrix for enhanced durability and impact resistance. The bits are suitable for drilling in medium to hard formations and are versatile enough for different drilling applications.2. Steel body PDC bitsSteel body PDC bits are designed with high-quality steel for superior strength and durability. The bits are suitable for drilling in soft to medium formations, from shallow to deep wells.3. IADC code pdc bitsPDC bits are classified based on the IADC (International Association of Drilling Contractors) code, which provides a standard for selecting suitable bits for different drilling applications. The code considers factors such as formation type, bit type, and hydraulic horsepower to determine the optimal bit for a particular application.Benefits of PDC Bits1. Improved penetration ratesPDC bits are designed with multiple cutting elements that provide faster penetration rates than traditional drill bits. The bits are designed to drill efficiently through different formations, reducing drilling time and the associated costs.2. Longer lifespanPDC bits have a longer lifespan compared to traditional drill bits. The polycrystalline diamond cutting elements are super-hard and resistant to wear, ensuring that the bits maintain consistent performance over long hours of drilling.3. Reduced downtimePDC bits are designed to withstand high-temperature and high-pressure conditions, reducing the need for frequent bit changes. This means less downtime and improved productivity during drilling operations.4. VersatilityPDC bits are versatile enough for different drilling applications, from oil and gas exploration to mining operations. The bits can drill efficiently through various formations, including hard and abrasive rock, shale, sandstone, and clay.Pdcbits: The Supplier of Quality PDC BitsPDC bits are a vital component of any drilling operation, and selecting the right supplier can impact the quality and efficiency of your drilling operations. At Pdcbits, we pride ourselves on providing high-quality PDC bits that meet the needs of our customers.Our PDC bits are designed and manufactured to exceed industry standards, ensuring exceptional performance and longevity. We offer a wide range of PDC bits, including matrix body PDC bits, steel body PDC bits, and IADC code PDC bits, suitable for different drilling applications.Our commitment to quality extends to our customer service. We provide reliable and responsive support, from product selection to after-sales support and maintenance. Our goal is to ensure that our customers' drilling operations are efficient, cost-effective, and safe.Pdcbits: Affordable PDC Bits PricelistAt Pdcbits, we understand that cost is an essential factor when choosing PDC bits. That's why we offer affordable prices for our high-quality PDC bits. We provide a pricelist for our PDC bits, making it easy for our customers to choose the best bit for their drilling operations.In conclusion, PDC bits are a game-changer in the drilling industry, offering superior performance, longevity, and versatility. With Pdcbits as your supplier, you can be assured of high-quality PDC bits that meet your drilling needs and budget. Contact us today for more information on our PDC bits and pricing.

Read More

- "Discover the Benefits of Owning a Water Well: Everything You Need to Know"

- "Unlocking the Potential of Water Wells: A Comprehensive Guide"

- "The Ultimate Guide to Water Wells: Everything You Should Consider"

- "Unveiling the Advantages of Water Wells: A Must-Read for Homeowners"

- "A Complete Overview of Water Wells: What You Need to Know"

- "Exploring the World of Water Wells: Essential Information for Prospective Buyers"

- "The Pros and Cons of Water Wells: Are they Right for You?"

- "Understanding Water Wells: A Layman's Guide to Getting Started"

- "Is a Water Well Right for Your Property? Key Factors to Consider"

- "Dive into the World of Water Wells: Tips and Insights for Property Owners

[Company Introduction: Background and Expertise][Company Name], a leading provider of water well services, has been revolutionizing the industry with its cutting-edge technologies and exceptional customer service. With a strong commitment to providing safe, reliable, and efficient solutions, [Company Name] has gained a reputation for delivering high-quality water wells to meet the growing needs of communities worldwide.Founded in [year], [Company Name] has built a team of experienced professionals who are dedicated to finding innovative and sustainable solutions for water supply challenges. With years of practical experience and abundant expertise in drilling, construction, and maintenance of water wells, our company has successfully executed numerous projects, both small-scale and large-scale, in diverse geographical locations.Our Approach to Water Well SolutionsAt [Company Name], we believe that access to clean and reliable water sources is a fundamental right of every individual. Therefore, we adopt a comprehensive approach to address the specific requirements and challenges of each project, ensuring that our clients receive the best possible outcome.Advanced Technology IntegrationWe leverage the latest technological advancements to streamline the water well drilling process, enhancing productivity, and minimizing the environmental impact. By employing state-of-the-art machinery and equipment, we are capable of drilling wells to exceptional depths, ensuring an abundant and sustainable water supply for our clients.Comprehensive Project ManagementOur team of experts conducts thorough site evaluations to assess the geology, hydrogeology, and other critical factors before initiating any drilling project. This meticulous planning ensures that our wells are constructed with precision and adhere to the highest industry standards. Furthermore, we work closely with our clients to understand their unique requirements, ensuring that all relevant regulations and guidelines are met.Sustainability and Environmental PreservationAs a responsible organization, sustainability is at the core of every decision we make. We strive to minimize the carbon footprint associated with water well construction and maintenance. Through the use of eco-friendly materials and efficient drilling practices, we ensure that the ecosystems surrounding our wells remain unharmed.[News Content: Water Wells Impacting Communities]Water scarcity continues to be a pressing global concern, affecting millions of people worldwide who lack access to safe and clean water sources. In line with its dedication to mitigating this issue, [Company Name] has successfully completed a transformative water well project in [location]. By drilling deep and sustainable wells, the company has provided a reliable source of potable water to thousands of people in the region.The project, which commenced in [year], was undertaken to serve as a sustainable solution to the water crisis faced by the local community. Prior to [Company Name]'s intervention, the community relied heavily on sporadic rainfall and distant water sources, often leading to waterborne diseases and compromised hygiene.The drilling experts at [Company Name] conducted rigorous geotechnical surveys to identify the most suitable locations for well construction. Using advanced technologies, they drilled deep into the ground, ensuring access to clean water reservoirs that could safeguard the community against droughts and contamination.To maximize the impact of the project, [Company Name] collaborated closely with local communities, governments, and NGOs, promoting community engagement and capacity building. Regular awareness programs were organized to educate locals about the proper maintenance and monitoring of wells, ensuring their longevity.The completion of this transformative project has not only provided access to clean water but has also enabled economic growth within the community. Engaging in agricultural activities, the locals can now cultivate crops with a more reliable water source, significantly improving food security and reducing dependency on external aid.[Company Name]'s commitment to quality and sustainability has been well-recognized, receiving accolades from local authorities and international organizations alike. The successful completion of this project represents yet another milestone in [Company Name]'s ongoing efforts to alleviate water scarcity and uplift communities around the world.As [Company Name] continues to contribute to water well solutions globally, its dedication to innovation, environmental preservation, and community partnerships remain the driving forces behind its success. By combining advanced technologies, comprehensive project management, and a strong commitment to sustainability, the company aims to create a future where everyone has access to safe and clean water, improving their quality of life.

Read More

New High-Tech Factory Opens for Valve Production

Title: Renowned Manufacturing Facility Demonstrates Dedication to Quality Products and Sustainable PracticesIntroduction:In an era where quality, reliability, and sustainability are paramount, one manufacturing facility has steadily elevated itself to become a global leader in the industry. This groundbreaking facility, known for its excellence in valve production, showcases an unwavering commitment to delivering top-notch products while prioritizing environmentally friendly practices. By incorporating cutting-edge technologies and fostering a skilled workforce, this factory has emerged as an epitome of success in the realm of industrial manufacturing.Background:Founded several decades ago, this manufacturing facility has continuously proven its mettle in valve production. With state-of-the-art infrastructure and modern machinery, the factory has successfully streamlined its manufacturing processes to optimize efficiency and maintain exceptional product quality. In addition to creating reliable and durable valve systems, the factory has embraced sustainability as a core principle, actively employing various environmentally friendly practices throughout its operations.Commitment to Quality:At the heart of the manufacturing facility's success is its unwavering commitment to quality. By investing in advanced machinery and adhering to strict quality control protocols, the factory ensures that each valve produced meets stringent industry standards. From robust materials selection to rigorous testing, every step of the manufacturing process is meticulously executed to guarantee exceptional performance and longevity of the final products.Furthermore, the factory has built a team of highly skilled engineers and technicians who possess an extensive understanding of valve technology. Through continuous research and development efforts, these professionals consistently push the boundaries of innovation, enabling the facility to introduce cutting-edge products that cater to diverse market requirements.Sustainable Manufacturing Practices:Recognizing their responsibility towards the environment, the manufacturing facility has implemented a range of sustainable practices to reduce their carbon footprint and promote eco-friendly production. This includes embracing energy-efficient technologies, investing in renewable energy sources, and adopting recycling and waste management programs.Their commitment to sustainability extends beyond their operational practices; the facility also focuses on utilizing environmentally friendly materials in the production of their valves. By strategically selecting materials that minimize environmental impact while maintaining uncompromised product quality, the factory strives to contribute to a greener and more sustainable future.Community Involvement and Corporate Social Responsibility:The manufacturing facility understands the importance of giving back to society and actively engages with local communities. The factory's corporate social responsibility initiatives include providing employment opportunities to the local workforce, prioritizing safety and welfare measures, and supporting various community development projects.In addition, the facility collaborates with educational institutions and vocational training programs to enhance the skills and capabilities of aspiring professionals. By promoting learning and development, the factory aims to cultivate a skilled workforce for the industry while fostering economic growth and social progress.Global Reach and Industry Recognition:As a result of their unwavering commitment to quality and sustainability, the manufacturing facility has gained international recognition for its products and practices. Their valves are widely used across various sectors, including oil and gas, water treatment, power generation, and construction.Furthermore, the factory has been honored with prestigious industry awards, acknowledging its technological advancements and dedication to exceptional manufacturing standards. Its contributions to sustainable practices have also earned it accolades in the form of environmental certifications, thus solidifying its position as a leading force in both quality valve production and sustainable manufacturing.Conclusion:The manufacturing facility has proven time and again that excellence and sustainability go hand in hand. With its meticulous attention to quality, cutting-edge technology, and commitment to environmental stewardship, this factory has become a beacon of success in the manufacturing industry. Through its unwavering dedication and community involvement, it serves as an inspiration for other companies to prioritize product quality, sustainable practices, and social responsibility.

Read More

Efficiently Milled Tooth Bit: The Ultimate Drilling Solution for Oil and Gas Operations

Title: IADC126 7.5" Milled Tooth Bit: An Effective Solution for Enhanced Drilling OperationsIntroductionIn the ever-evolving oil and gas industry, drilling experts continually seek innovative solutions to optimize performance and increase efficiency. As drilling activities become more challenging and demanding, it is crucial to have reliable equipment that can withstand harsh conditions while delivering exceptional results. One such equipment that has gained prominence in recent times is the IADC126 7.5" Milled Tooth Bit, designed to revolutionize drilling operations and ensure optimum productivity.Product OverviewThe IADC126 7.5" Milled Tooth Bit combines cutting-edge technology with superior craftsmanship to create an advanced drilling tool. Manufactured by an industry-leading drilling equipment provider (insert company name), this dynamic bit adheres to the highest quality standards and is engineered to meet the rigorous demands of today's drilling projects. With a focus on durability, efficiency, and precision, this bit is tailored to tackle a wide range of challenging drilling conditions.Advanced Design and FeaturesThe IADC126 7.5" Milled Tooth Bit boasts several revolutionary design features that set it apart from conventional alternatives. The bit is carefully constructed using premium quality materials for exceptional strength and longevity, making it a cost-effective choice for drilling operations. Moreover, the bit's unique tooth profile, combined with its optimized cutting structure, ensures efficient and rapid penetration while minimizing the risk of bit damage.Furthermore, the IADC126 7.5" Milled Tooth Bit incorporates state-of-the-art nozzles that enable effective cleaning and cooling of the cutting structure, enhancing overall drilling performance. The strategically placed nozzles direct high-velocity fluid streams to clear drilling cuttings effectively, maintaining a clean and debris-free wellbore.Versatility and AdaptabilityThe versatility of the IADC126 7.5" Milled Tooth Bit is another noteworthy aspect of its design. Its adaptability to various drilling environments, including soft to medium formations, empowers drilling teams to complete projects swiftly and removes the need for frequent bit changing operations. This efficiency not only saves time but also reduces overall drilling costs, making it an invaluable asset for drilling contractors and operators.Enhanced ProductivityBy delivering exceptional rate of penetration (ROP) and reducing the number of trips required to the surface, the IADC126 7.5" Milled Tooth Bit significantly enhances drilling productivity. Its cutting-edge design minimizes downhole vibrations and torque, leading to improved efficiency and tool life. Additionally, the bit's thorough removal of cuttings enhances hole cleaning, reducing the risk of stuck pipe incidents and other drilling challenges.Reliability and Support(Insert company name) stands behind the IADC126 7.5" Milled Tooth Bit with an unwavering commitment to customer satisfaction. Backed by a team of experienced engineers and technical support staff, the company provides comprehensive assistance and guidance to drilling teams using their equipment. This dedication to after-sales service ensures that drilling operations can proceed smoothly and efficiently, minimizing downtime and maximizing productivity.ConclusionIn an industry where performance and efficiency are paramount, the IADC126 7.5" Milled Tooth Bit emerges as a game-changer. Boasting advanced design features, adaptability to various drilling conditions, and superior customer support, this state-of-the-art drilling tool redefines productivity and reliability. With its exceptional performance and long-lasting durability, the IADC126 7.5" Milled Tooth Bit is poised to revolutionize drilling operations across the globe, cementing its position as the go-to solution for enhanced drilling efficiency.

Read More

Hard Rock Drilling Thread Button Bits for Mining - 15 Buttons, 115mm Tungsten Carbide

Read More

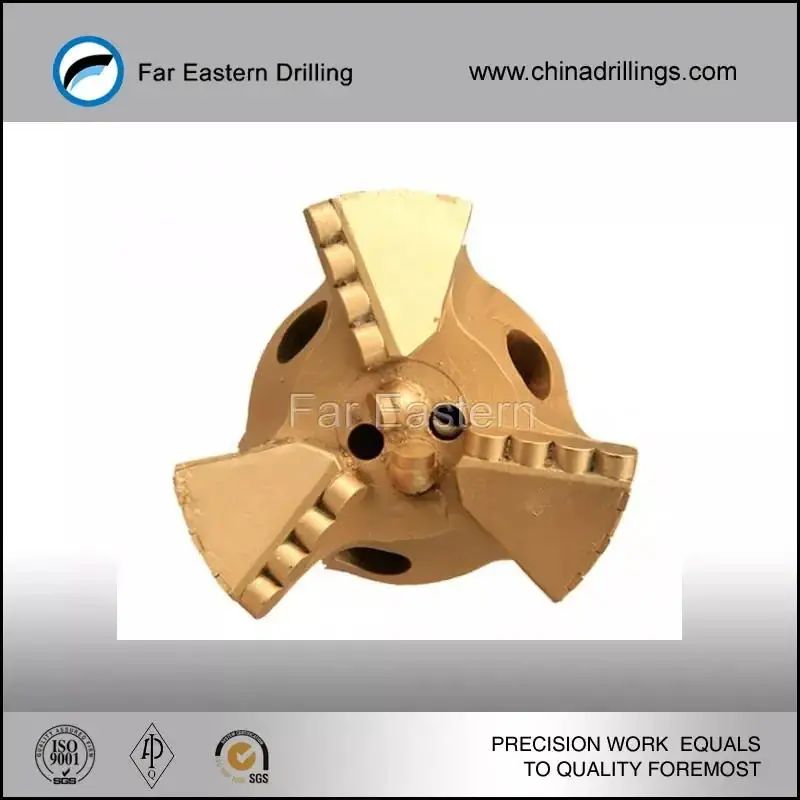

7 1/2 TCI Tricone Bit for Water and Petroleum Well Drilling - IADC517 Standard

TCI petroleum tricone bit is an important tool in petroleum and water well drilling operations. It is designed to handle a wide range of geological formations with varying degrees of hardness. The tricone bit is a three-cone drill bit with Tungsten Carbide Inserts (TCI) on each cone. These inserts are made of hard, wear-resistant Tungsten Carbide, which can withstand extreme drilling conditions and high temperatures.The API 7 1/2 IADC517 TCI Tricone Bit is a specially designed tricone bit that is ideal for drilling in rock formations that have high compressive strength. This tricone bit has been designed to operate in a variety of drilling conditions and can be used for both petroleum and water well drilling. It is made from high-quality materials, making it highly durable and long-lasting.One of the key advantages of using a TCI petroleum tricone bit is that it can drill through almost any rock formation. This is because Tungsten Carbide is highly resistant to wear and tear, and can handle high compressive loads. This makes it ideal for drilling in hard rock formations, which can be difficult to penetrate using other types of drill bits.In addition to high compressive strength, the API 7 1/2 IADC517 TCI Tricone Bit is also designed to handle high temperatures. This is important, as drilling operations can generate a lot of heat, which can damage the drill bit. However, the TCI inserts are capable of withstanding high temperatures, ensuring that the drill bit remains operational even in extreme conditions.Another advantage of using a TCI petroleum tricone bit is that it is highly accurate. The three cones of the tricone bit work together to create a smooth, consistent drill pattern, which helps to reduce the risk of deviation or deviation during drilling operations. This is especially important in petroleum and water well drilling operations, where accuracy is crucial to ensuring the success of the project.Overall, the API 7 1/2 IADC517 TCI Tricone Bit is an excellent choice for petroleum and water well drilling operations. It is highly durable, long-lasting, and can handle a wide range of geological formations. With its ability to withstand high compressive loads and temperatures, it is a tool that is built to last. If you are looking for a reliable and effective tricone bit for your drilling operations, the TCI petroleum tricone bit is an excellent choice that will give you great results every time.

Read More