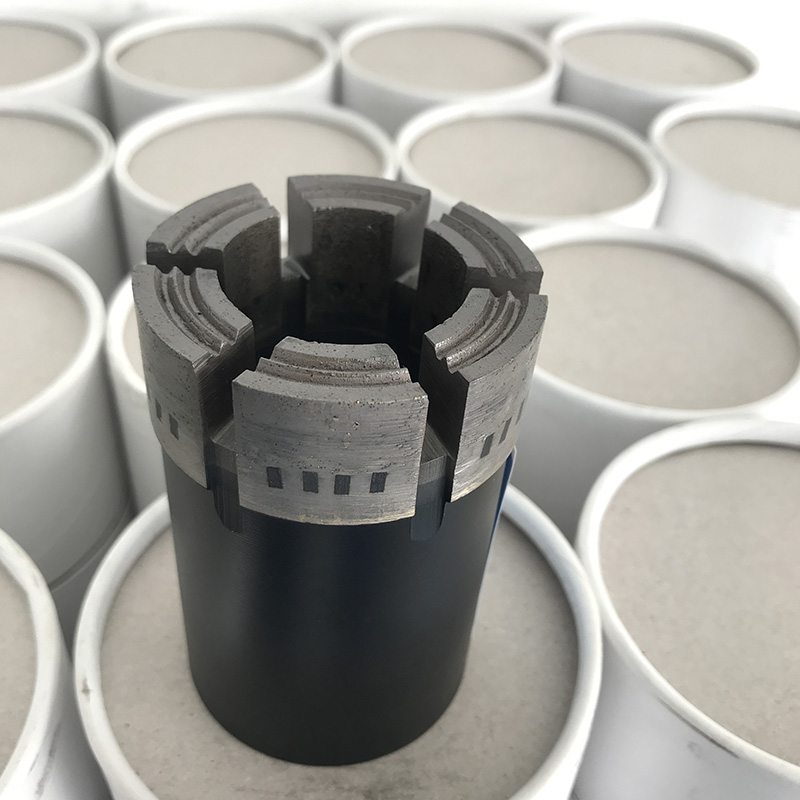

Durable Mill Tooth Bit IADC217 444.5mm for Efficient Drilling

By:Admin

The mill tooth bit IADC217 444.5mm is designed to meet the growing demand for efficient and reliable drilling equipment. With its advanced technology and high-quality materials, this bit is capable of delivering exceptional results in a wide range of drilling applications. Its innovative design allows for enhanced penetration rates and improved durability, making it an ideal choice for challenging drilling environments.

One of the key features of the mill tooth bit IADC217 444.5mm is its unique tooth design, which is optimized for maximum cutting efficiency. This allows for faster and more efficient drilling, resulting in significant time and cost savings for drilling operations. Additionally, the bit is constructed from high-grade materials that are highly resistant to wear and abrasion, ensuring long-lasting performance in the field.

In addition to its superior performance, the mill tooth bit IADC217 444.5mm is also designed with ease of use in mind. Its innovative design allows for quick and easy installation, reducing downtime and increasing productivity on the job site. This makes it an ideal choice for drilling operations of all sizes, from small-scale projects to large-scale industrial operations.

Furthermore, the company's commitment to quality and innovation is evident in the development of the mill tooth bit IADC217 444.5mm. With a focus on research and development, the company is constantly seeking new ways to improve its products and meet the evolving needs of the industry. This dedication to innovation has allowed the company to maintain its position as a leader in the field, providing customers with reliable and high-performance drilling solutions.

As a result of the company's dedication to excellence, the mill tooth bit IADC217 444.5mm has already garnered significant interest from industry professionals. Its advanced features and superior performance make it a valuable addition to any drilling operation, offering the potential for improved efficiency and cost savings. With its proven track record of delivering high-quality products, the company is well-poised to make a significant impact with the introduction of this new tool.

In conclusion, the introduction of the mill tooth bit IADC217 444.5mm represents an important milestone for the company, further solidifying its position as an industry leader in the oil and gas sector. With its innovative design, advanced technology, and proven performance, this new product is expected to make a significant impact on drilling operations around the world. As the company continues to push the boundaries of drilling technology, customers can expect to see even more groundbreaking innovations in the future.

Company News & Blog

Get Your Hands on a Mini Cordless Rechargeable Electric Screwdriver Bit Set Drill with Free Delivery on HammerDrill.org.uk

Looking for a mini cordless electric drill to handle your small DIY projects? Look no further than the Drill bit sets/spares2go mini cordless rechargeable electric screwdriver bit set drill. This versatile tool is great for home repairs, crafting, and even light woodwork.The Drill bit sets/spares2go mini cordless rechargeable electric screwdriver bit set drill is lightweight, yet powerful. With a 3.6-volt motor, it can easily drill through plastic, wood, and even soft metals. And, at only 7 inches long, it's perfect for tight spaces.One of the benefits of this electric drill is its rechargeable battery. You won't have to worry about constantly buying replacement batteries. Simply charge it up and you're ready to go. It also comes with several drill bits, so you'll be prepared to take on a variety of projects.Speaking of drill bits, if you're in the market for drill bits for oil drilling, you may want to consider choosing high-speed steel or cobalt drill bits. These materials are known for their strength and durability, making them ideal for drilling through tough materials like hard metals, including steel and iron.When choosing drill bits, it's important to consider the size and shape of the bits. Oil drilling often requires large bits for drilling through thick materials, so be sure to choose bits that fit the size of your well.In addition to choosing the right bits, it's also important to maintain them properly. This means keeping them sharp and free from debris. When drilling through oil, it's especially important to remove any debris from the bits, as this can cause damage to the drill and, in some cases, lead to dangerous situations.In conclusion, if you're in need of a mini cordless electric drill for your DIY projects, the Drill bit sets/spares2go mini cordless rechargeable electric screwdriver bit set drill is a great option. And if you're drilling for oil, be sure to choose high-quality drill bits that are properly sized and maintained.

Industry-Leading 10-Inch Hole Opener Manufacturer Offers Premium Quality Products

Title: Leading Hole Opener Factory Expands its Product Line to Meet Growing DemandIntroduction:, - With the continuous development and expansion of the drilling industry, the demand for high-quality drilling equipment has significantly increased. One prominent player in the market, a reputable hole opener factory widely recognized for its cutting-edge technology and commitment to customer satisfaction, is now proud to announce the expansion of its product line to cater to the growing demand.Company Background:Established several decades ago, this industry-leading hole opener expert has grown into one of the most reliable manufacturers with a solid reputation for delivering superior quality products. Combining innovative design with advanced engineering techniques, the company has successfully cemented its position as a trusted partner for both domestic and international drilling operations.News Content:In response to the increasing market demands for larger hole sizes in drilling operations, the hole opener factory has decided to introduce a versatile and efficient 10-inch hole opener to its product line. This new addition aims to provide drilling professionals with a comprehensive solution to optimize their operations, saving both time and costs.At the heart of the product lies the company's unwavering commitment to innovation and quality. The 10-inch hole opener has been meticulously designed with the latest technological advancements to ensure maximum performance in various drilling conditions. Its robust construction and precision-engineered cutters allow for high penetration rates and exceptional durability, ensuring longevity in the field.Furthermore, the company understands the diverse requirements of its clients and acknowledges that customization plays a crucial role in meeting their unique needs. To align with this aspect, the hole opener factory offers a range of customization options for the 10-inch hole opener. Customers can choose from an array of cutter designs, bearing configurations, and other specifications, enabling them to tailor the tool to their specific drilling requirements.Recognizing the significance of timely delivery, the hole opener factory emphasizes its commitment to quick turnaround times. With streamlined production processes and state-of-the-art manufacturing facilities, the company ensures swift delivery to customers worldwide, fostering strong and reliable partnerships.A spokesperson for the hole opener factory highlighted the benefits of the newly introduced 10-inch hole opener, stating, "We are excited to add this versatile tool to our product line. By expanding our offerings, we aim to empower drilling professionals to achieve precise and efficient drilling operations while minimizing downtime. The 10-inch hole opener is a testament to our continuous commitment to meeting the evolving needs of the industry."The introduction of the 10-inch hole opener reinforces the hole opener factory's position as an industry leader and marks a significant milestone in its journey. The factory remains dedicated to providing exceptional products, unwavering customer support, and cutting-edge solutions to meet and exceed industry demands.Conclusion:As the drilling industry continues to evolve, the demand for efficient, reliable, and custom-built drilling tools becomes increasingly critical. The expansion of the hole opener factory's product line to incorporate the durable and versatile 10-inch hole opener showcases the company's commitment to meeting these demands head-on. With its innovative design, precision engineering, and customization options, the 10-inch hole opener offers drilling professionals a solution that enhances productivity while maintaining the highest standards of performance and quality.

Top Tricone and PDC Bit Factory in Hebei Province, China

The oil and gas industry is an ever-growing industry that requires constant innovation to keep up with the growing demand for energy. The drilling process is one of the most important stages in oil and gas exploration, and the quality of the drilling equipment used can have a significant impact on the efficiency of the drilling process. PDC and tricone drill bits are two popular drilling tools that are widely used in the industry.PDC (polycrystalline diamond compact) bits are made of small synthetic diamonds that are bound together chemically and thermally to form a single piece. They are known for their high durability, resistance to wear and tear, and their ability to maintain their sharp edges for longer periods. PDC bits are used for drilling through soft to medium-hard rock formations.Tricone bits, on the other hand, are made of three cones that rotate together to drill into rock formations. Each cone has teeth or inserts that help to break the rock as it rotates. Tricone bits are known for their versatility and ability to drill through different rock formations, from soft shale to hard granite.Finding the right PDC tricone bits factories can be a challenge for companies in the oil and gas industry. However, there are several key factors to consider when choosing a factory to supply your drilling equipment.Quality ControlThe quality of the drilling equipment supplied by the factory is one of the most important factors to consider. The factory should have a robust quality control system in place to ensure that the equipment meets industry standards and is fit for purpose. Look for a factory that has ISO 9001 certification, which indicates that they have a quality management system in place.Experience and ExpertiseExperience and expertise are critical when it comes to drilling equipment manufacturing. Look for a factory that has been in the industry for several years and has a wealth of experience in manufacturing PDC and tricone drill bits. They should have a team of experts in the field who are knowledgeable about the latest drilling technologies and can offer advice on the best equipment to use for specific drilling projects.Production Capacity and EfficiencyThe production capacity and efficiency of the PDC tricone bits factory are also important factors to consider. Look for a factory that has invested in modern technologies and equipment that can produce high-quality drilling equipment in large quantities. A factory with efficient production processes can help to reduce lead times and ensure that you receive your equipment on time.Customer Service and SupportFinally, customer service and support are also crucial when choosing a PDC tricone bits factory. Look for a factory that is responsive to your needs and can provide timely support and assistance when required. They should have a dedicated customer service team that can answer your queries and provide technical support.In conclusion, choosing the right PDC tricone bits factory is essential if you want to ensure the efficiency and effectiveness of your drilling projects. Consider factors such as quality control, experience, production capacity, and customer service when choosing a factory to supply your drilling equipment. With the right factory, you can be assured of high-quality equipment that meets the specific requirements of your drilling projects.

IADC 735 7 7/8" Drilling Bits: Everything You Need to Know

[Company Name] Introduces New 7 7/8" Drilling Bits for Enhanced Efficiency in Oil and Gas Exploration[City, Date] - [Company Name], a leading provider of drilling and oilfield equipment, is proud to announce the launch of their new 7 7/8" drilling bits. These state-of-the-art bits are designed to offer enhanced efficiency and performance in oil and gas exploration operations.The 7 7/8" drilling bits are equipped with the latest cutting-edge technology, making them ideal for use in a wide range of drilling applications. These bits are manufactured to the highest standards, utilizing premium quality materials and advanced engineering techniques to ensure superior performance and reliability.One of the key features of the 7 7/8" drilling bits is their innovative design, which enhances the speed and effectiveness of the drilling process. The carefully engineered cutting structure of the bits ensures optimal penetration rates and consistent performance, resulting in significant time and cost savings for oil and gas companies.Furthermore, the 7 7/8" drilling bits are designed to withstand the harshest drilling conditions, making them suitable for use in challenging environments. Their robust construction and durable materials ensure long-lasting performance, reducing the need for frequent replacements and maintenance.In addition to their exceptional performance, the 7 7/8" drilling bits are also designed with safety and environmental considerations in mind. The bits are engineered to minimize the risk of accidents and environmental impact, ensuring a responsible and sustainable approach to oil and gas exploration.[Company Name] is committed to providing the highest quality drilling and oilfield equipment to meet the evolving needs of the industry. With a focus on innovation and excellence, the company continuously invests in research and development to bring cutting-edge solutions to the market.The introduction of the 7 7/8" drilling bits is a testament to [Company Name]'s dedication to providing state-of-the-art equipment that delivers superior performance and value to its customers. The company's extensive experience and expertise in the drilling and oilfield industry make it a trusted partner for oil and gas companies around the world."We are excited to introduce our new 7 7/8" drilling bits to the market," said [Spokesperson Name], [Title] at [Company Name]. "These bits are the result of our ongoing commitment to innovation and excellence, and we are confident that they will provide significant benefits to our customers in their drilling operations."The 7 7/8" drilling bits from [Company Name] are now available for purchase, and the company is ready to meet the increasing demand from customers around the world. With their superior performance, durability, and safety features, these bits are set to become a valuable asset for oil and gas exploration companies seeking to enhance their drilling operations.For more information about the 7 7/8" drilling bits and other products offered by [Company Name], please visit [company website].

Powder Metallurgy Process Creates Rotary Cone Drill Bit for Oil Wells

Drilling for oil and gas is a challenging and demanding task, and it requires specialized equipment and technology to get the job done efficiently. One of the crucial tools used in drilling is the rotary cone drill bit. These drill bits come in different shapes and sizes, but the milled tooth shape is one of the most commonly used shapes in the industry.Milled tooth drill bits have been around for over a century, and they are still widely used because of their reliability and durability. These bits are designed with a series of milled teeth that crush the rock as they rotate. Each tooth has a unique shape and configuration that allows it to efficiently cut through the different rock formations encountered during drilling.One of the benefits of milled tooth drill bits is their versatility. They can be used to drill through hard, abrasive formations, as well as softer formations. Milled tooth drill bits are suitable for drilling wells of different sizes, depths, and applications. They are commonly used in the oil and gas industry, but they can also be used in other applications, such as mining and geothermal drilling.IADC126 and 660mm are two common specifications for milled tooth drill bits. IADC stands for the International Association of Drilling Contractors, and it is a classification system used to identify the type and performance of drill bits. The IADC126 code indicates a mill tooth drill bit with medium to hard formation suitability and low wear rate. 660mm refers to the diameter of the drill bit.Manufacturing milled tooth drill bits is a complex process that involves different stages. One of the latest methods used in manufacturing is powder metallurgy. This process involves mixing metal powders to form an alloy, which is then pressure molded into the desired shape of the drill bit. The molded bit is then sintered at high temperatures to fuse the powder particles together and form a solid structure. Finally, the bit is precision machined to create the final shape, size, and configuration of the milled teeth.The powder metallurgy process offers several benefits over traditional manufacturing methods. It allows for higher precision, consistency, and efficiency in the production of milled tooth drill bits. Powder metallurgy can also use a wide range of alloys and materials, making it a versatile and flexible manufacturing method.In conclusion, milled tooth drill bits are an essential tool in the oil and gas industry and other drilling applications. The IADC126 and 660mm specifications are common for these drill bits, and the powder metallurgy process is a modern and efficient method of manufacturing them. By investing in reliable and high-quality milled tooth drill bits, drilling operations can be performed more efficiently and safely, leading to improved production and profitability.

Specialized Factory Produces High-Quality 120mm Bits for Drilling Industry

A leading global supplier of drilling bits, IADC517 120mm bit factory, recently announced the opening of its newest manufacturing facility. With a focus on innovation and advanced technology, the new factory is aimed at meeting the growing demand for high-performance bits in the oil and gas industry.The IADC517 120mm bit factory offers a wide range of drilling bits designed to deliver superior performance in various drilling applications. Using cutting-edge technology and state-of-the-art equipment, the factory produces some of the most advanced and durable drill bits in the market.According to company sources, the IADC517 120mm bit factory employs a team of highly skilled professionals who work tirelessly to ensure that every bit manufactured meets the highest quality standards. The team is committed to continuous innovation and improvement, constantly looking for new ways to enhance the performance, durability, and reliability of their products.In addition to its commitment to quality and innovation, the IADC517 120mm bit factory is also dedicated to sustainability. The factory uses environmentally friendly manufacturing processes and sources its materials from ethical and sustainable suppliers. This not only helps to minimize the impact of the factory's operations on the environment but also ensures that the company's products are ethically sourced and produced.The new facility will significantly increase the company's production capacity, enabling it to meet the growing demand for high-quality drilling bits. This is especially important given the current state of the global oil and gas market, which has seen increased exploration and production activities in both conventional and unconventional reservoirs.The IADC517 120mm bit factory's reputation for quality and performance is well known in the industry. The company's products are trusted by drilling professionals around the world, and its expertise in the field is unmatched.The opening of the new manufacturing facility is just the latest in a series of moves aimed at expanding the company's reach and improving its offerings. With a focus on innovation, quality, and sustainability, the IADC517 120mm bit factory is poised for continued growth and success in the years to come.As per the reports, the IADC517 120mm bit factory is already a renowned name all over the globe for its high-quality drill bits that are designed to meet the diverse needs of the oil and gas industry. The company has a rich history that goes back several decades, and during this period, it has established itself as one of the leading manufacturers of drilling bits in the world.The IADC517 120mm bit factory is known for its commitment to quality and innovation. The company has always been at the forefront of cutting-edge technology, and it has an in-house research and development team that is always on the lookout for new and improved methods to enhance the performance and durability of its products.The company's drilling bits are designed to provide superior performance in a range of drilling applications, from conventional reservoirs to unconventional shale formations. This has made the company a trusted partner to drilling professionals, who rely on its products to increase drilling efficiency and reduce costs.The IADC517 120mm bit factory has a strong commitment to sustainability and ethical practices. The company sources its materials from sustainable suppliers and uses environmentally friendly manufacturing processes to minimize its impact on the environment. This commitment to sustainability has helped the company build a strong reputation that extends far beyond the oil and gas industry.Conclusion:The opening of the new IADC517 120mm bit factory is a testament to the company's dedication to continued growth and innovation. The new manufacturing facility will enable the company to increase its production capacity and meet the growing demand for high-quality drilling bits in the oil and gas industry.As the industry continues to evolve, the IADC517 120mm bit factory remains committed to staying at the forefront of technological advancements and innovation. By continuing to invest in research and development and maintaining its reputation for quality and performance, the company is well poised for continued growth and success in the years to come.

Top supplier of PDC drill bits for well drilling applications

The well drilling industry is constantly evolving, with advancements in technology and equipment paving the way for more efficient and effective drilling processes. One crucial piece of equipment in well drilling is the PDC (polycrystalline diamond compact) bit, which is used to crush and cut rock formations as the drill bit rotates. As one of the leading suppliers of PDC bits, {} has been at the forefront of innovation in this field, providing high-quality and reliable PDC bits to meet the diverse needs of the well drilling industry.With a focus on delivering cutting-edge solutions, {} has established itself as a trusted and reputable supplier of PDC bits. The company's commitment to quality and customer satisfaction has set them apart in the industry, making them the go-to choice for well drilling companies around the world. By combining state-of-the-art technology with industry expertise, {} has been able to develop PDC bits that deliver superior performance and durability in even the most challenging drilling environments.One of the key factors that sets {} apart from other PDC bit suppliers is their dedication to research and development. With a team of experienced engineers and technicians, {} is constantly striving to enhance their PDC bit designs and materials to ensure optimal drilling efficiency and productivity. This commitment to innovation has led to the development of cutting-edge PDC bit technologies that have revolutionized the well drilling process, allowing companies to achieve higher levels of performance and cost-effectiveness.In addition to their focus on innovation, {} also places a strong emphasis on quality control and precision manufacturing. Every PDC bit produced by {} undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and reliability. By utilizing advanced manufacturing processes and materials, {} is able to consistently produce PDC bits that outperform the competition and deliver long-term value to their customers.Furthermore, {} is dedicated to providing personalized service and support to their clients. The company's team of technical experts works closely with customers to understand their specific drilling requirements and challenges, and then provides tailored solutions to meet their individual needs. This personalized approach has earned {} a reputation for being responsive and reliable, making them the preferred choice for well drilling companies seeking a trusted partner for their PDC bit needs.As a global leader in PDC bit supply, {} has built a strong and loyal customer base, with a presence in numerous markets around the world. The company's commitment to excellence, combined with their extensive product range and technical expertise, makes them a preferred supplier for a wide range of well drilling applications. Whether it's for oil and gas exploration, geothermal drilling, mining, or water well construction, {} has the capabilities to deliver high-performance PDC bits that exceed industry expectations.Moving forward, {} remains focused on driving innovation and delivering unmatched value to their customers. With a relentless pursuit of excellence and a commitment to customer satisfaction, {} is poised to continue leading the way in the well drilling industry and setting new standards for PDC bit performance and reliability. As the demand for efficient and cost-effective drilling solutions continues to grow, {} is well positioned to meet the evolving needs of the industry and provide the innovative PDC bits that are essential for success in today's competitive well drilling market.

Unlocking the Potential: Exploring the Latest Innovations in Oil Drill Bits

[Company Introduction][Company Name] is a leading manufacturer and supplier of cutting-edge oil drilling equipment and technology. With a strong reputation for quality and innovation, our company has been at the forefront of the oil and gas industry for over three decades. Our commitment to excellence has enabled us to build strong relationships with major oil companies and drilling contractors worldwide.With state-of-the-art manufacturing facilities and a dedicated team of engineers and technicians, we strive to develop and produce the finest oil drill bits on the market. Our products are designed to withstand the most challenging drilling environments, ensuring optimal performance, durability, and safety. We constantly push the boundaries of technology to deliver solutions that maximize drilling efficiency while minimizing downtime and associated costs.[Company Name] takes great pride in its customer-centric approach. We understand the unique requirements of each drilling project and collaborate closely with our customers to customize our products to their specific needs. Our experienced engineers provide technical assistance throughout the drilling process, helping customers achieve optimal results and enhancing their overall drilling operations.Moreover, maintaining environmental sustainability is a core value of our company. We prioritize the development and utilization of products and technologies that minimize environmental impact. By consistently improving our manufacturing processes and adopting responsible practices, we aim to contribute to a greener future for the oil and gas industry.[News Content][City], [Date] - In a major development for the oil and gas industry, [Company Name] has unveiled its latest range of oil drill bits, marking a significant milestone in drilling technology. These new drill bits are set to revolutionize the drilling process, offering unprecedented levels of efficiency, reliability, and durability.With a focus on constant innovation, [Company Name]'s research and development team has spent years fine-tuning these advanced drill bits, ensuring they meet and exceed the evolving needs of the industry. The result is a breakthrough technology that promises to enhance drilling operations across the globe.The new oil drill bits boast a unique design that optimizes their cutting ability, enabling them to effortlessly penetrate even the most complex geological formations efficiently. This innovation significantly reduces drilling time and enhances productivity, translating to substantial cost savings for drilling contractors and oil companies.Furthermore, the new drill bits incorporate a proprietary material that enhances their durability while maintaining a high level of heat resistance. This ensures a prolonged lifespan, reducing the frequency of bit replacements and minimizing downtime during drilling operations. The seamless performance of these drill bits also contributes to increased safety for rig personnel, as they can work with confidence in challenging drilling environments.In line with the company's commitment to sustainability, the new oil drill bits have been developed with environmentally-friendly features in mind. By reducing drilling time, these bits help in the minimization of carbon emissions associated with the drilling process. Additionally, their robust design and durability reduce waste generation, promoting responsible resource management and reducing the industry's ecological footprint.The launch of these cutting-edge drill bits is expected to create a significant impact on the oil and gas industry, providing drilling contractors and oil companies with a competitive edge. The enhanced drilling efficiency, durability, and environmental sustainability offered by [Company Name]'s oil drill bits ensure that they will be highly sought after in the market."We are thrilled to introduce our latest range of oil drill bits to the industry," said [Company Representative]. "Our dedicated team has worked tirelessly to develop a product that not only meets but exceeds the expectations of our customers. With these new drill bits, we aim to revolutionize drilling practices and set new standards for efficiency, reliability, and sustainability."With the launch of these state-of-the-art oil drill bits, [Company Name] continues to solidify its position as an industry leader. Their commitment to technological advancement and customer satisfaction ensures that drilling processes are taken to new heights, benefiting both the industry and the environment.